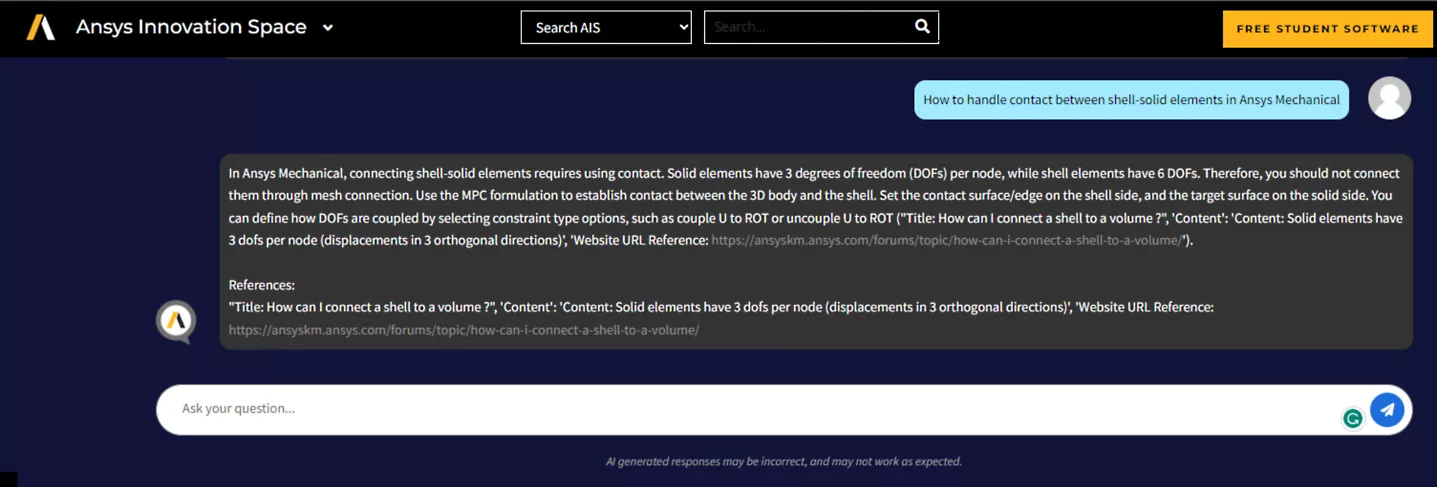

Expanding artificial intelligence (AI) integration across its simulation portfolio and customer community, Ansys announced the limited beta release of AnsysGPT, a multilingual, conversational, AI virtual assistant set to revolutionize the way Ansys customers receive support. Developed using state-of-the-art ChatGPT technology available via the Microsoft Azure OpenAI Service, AnsysGPT uses well-sourced Ansys public data to answer technical questions concerning Ansys products, relevant physics, and engineering topics within one comprehensive tool.

Expected in early 2024, AnsysGPT will optimize technical support for customers — delivering information and solutions more efficiently, furthering the democratization of simulation. While currently in beta testing with select customers and channel partners, upon its full release next year AnsysGPT will provide easily accessible 24/7 technical support through the Ansys website. Unlike general AI virtual assistants that use unsupported information, AnsysGPT is trained using Ansys data to generate tailored, applicable responses drawn from reliable Ansys resources including, but not limited to, Ansys Innovation Courses, technical documentation, blog articles, and how-to-videos. Strong controls were put in place to ensure that no proprietary information of any kind was used during the training process, and that customer inputs are not stored or used to train the system in any way.

“Ansys consistently delivers innovative solutions for its customers and with the beta release of AnsysGPT, Ansys once again stands at the forefront of the latest and most advanced technology,” said Erke Wang, managing director at CADFEM, an Elite Ansys Channel Partner. “By progressing customer support with AI-powered services, AnsysGPT will assist our team in delivering adaptive intelligence combined with expertise and training that empowers Ansys customers to extract even more value from Ansys solutions.”

In addition to providing expedited technical support, AnsysGPT will encourage customers’ individual learning and development by identifying appropriate resources to further examine specific topics of interest, including how AI/machine learning (ML) can enhance Ansys simulation.

“When trained responsibly, AI-powered virtual services can be a huge asset to both organizations and customers. AnsysGPT has been trained using Ansys data, which increases its reliability for Ansys customers,” said Anthony Dawson, vice president of customer excellence at Ansys. “Further, AnsysGPT complements existing AI integration across Ansys’ portfolio, including computational fluid dynamics (CFD) solvers that leverage AI/ML to improve turbulence models, structural tools that apply AI/ML to predict computational spend, and process integration and design optimization software that employs AI/ML to efficiently build reduced order models. We are confident AnsysGPT will add great value to our customer experience, providing more seamless support and useful information for Ansys customers.”

Ansys

ansys.com