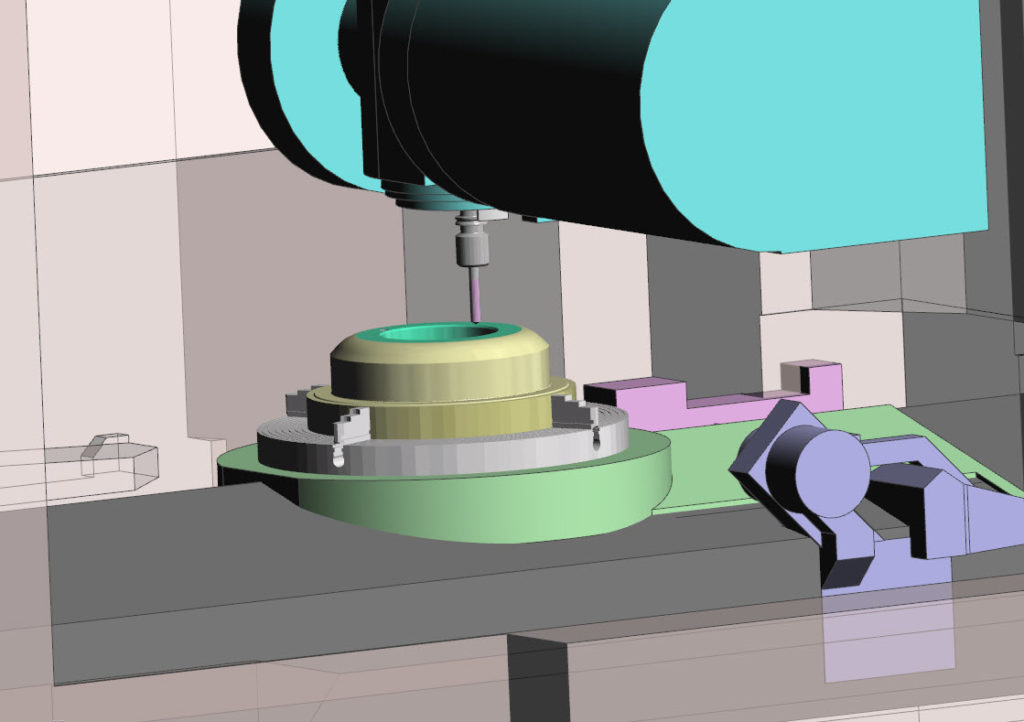

Hexagon’s Manufacturing Intelligence division announced it is exhibiting the newest releases of EDGECAM and WORKNC at WESTEC 2021, Long Beach Convention Center, Long Beach, CA, from November 16 -18, 2021. In Hexagon Booth #945, attendees will find CAD/CAM software technologies offering future-ready features for trending advancements in manufacturing. EDGECAM 2022’s newly-added support for 6-axis milling and turning machines enables programming of the cutter head into positions previously out of reach in just one set-up, which in the past required a series of sequences. The software also supports 3+2 machining and complex 5-axis simultaneous milling in all configurations. Also integrated with EDGECAM is a new component called NCSIMUL Essential providing full simulation of 3-axis milling parts. NCSIMUL is Hexagon’s high-end CNC simulation software for G-code verification. Users can dynamically interact with a toolpath and pinpoint exactly which line of code is being simulated. WESTEC visitors can see these late-breaking EDGECAM features and more demonstrated at regular intervals during the show.

Hexagon will also highlight the latest version of WORKNC computer-aided manufacturing (CAM) software designed for mold and die makers. The software’s newest enhancement is the integration of a ‘manufacturing aware’ computer-aided design (CAD) application called DESIGNER. All WORKNC users now have on-demand access to CAD functionality to heal missing faces, extend surfaces, and cap holes and pockets in preparation for manufacturing. Users can also employ a hybrid design approach combining surface and solid entities using direct modeling techniques. A one-click transfer of completed designs directly into the CAM software makes the entire process even faster for efficient production. Also notable are the new advances in WORKNC’s programming capabilities that reduce the time spent calculating toolpaths and help to generate faster, more efficient code for reduced cycle times.

During WESTEC, Hexagon will also feature several other technologies including the new-to-market reverse engineering software REcreate which enables users to move from a point cloud to mesh to solid in order to create manufacturing-ready formats. For visitors interested in metrology solutions, the new generation Inspire inspection software will be shown interfacing with Absolute Arms, a Leica Absolute Tracker, and the latest in ultra high-speed laser scanners – the Absolute Scanner AS1. The TEMPO part loading system will be demonstrated with a TIGO coordinate measuring machine (CMM), which facilitates innovative autonomous measurement and lights out quality control. The latest m&h probing systems for machine tool measurement will also make their debut at WESTEC.

Hexagon

hexagonMI.com