Repurposing designs saves design time and money, helping you get to market faster.

By Jean Thilmany, Senior Editor

Sometimes you don’t need to re-invent the wheel. You could, for instance, drop the computer-aided design file for an existing wheel into your lawnmower design. Many companies, particularly those that create custom parts or manufacturing systems, integrate already-created CAD parts into an assembly to shave design time.

That’s the idea behind configuration-based design, which allows users to drop an already-created design file into a part or assembly for quick customization. With configuration-based design, the CAD file automatically sizes and fits itself into the assembly.

While today’s CAD systems continue to add that functionality, IronCAD was the originator of the concept with the company’s launch in 1998, says Cary O’Connor vice president of marketing at IronCAD, Atlanta.

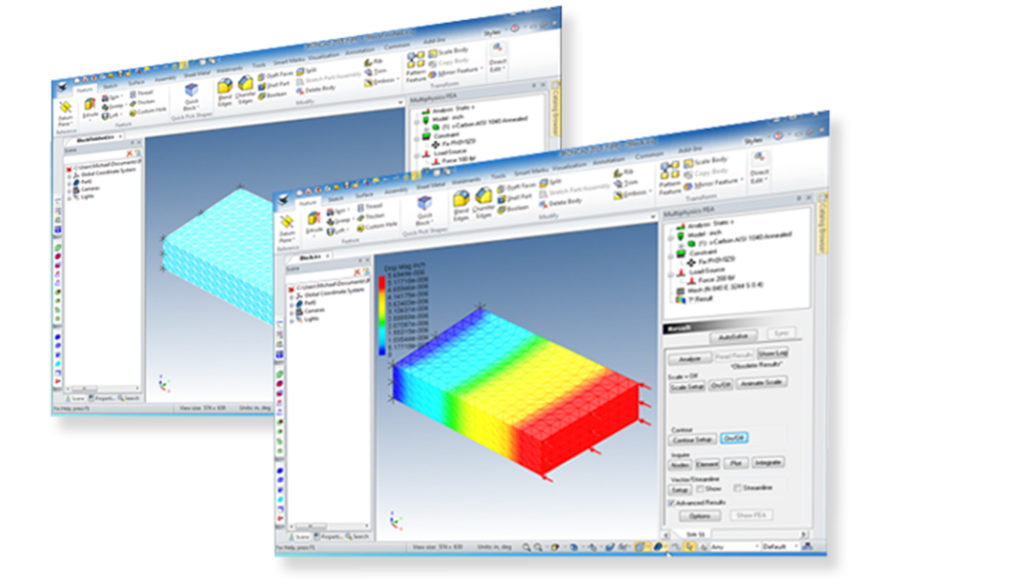

With this method, feature, part, and assembly data for each part are stored in a catalog of frequently used parts and assemblies. The piece from the catalog provides precise reference locations when designers drop their components into a larger design, positioning it automatically into any complex orientation required, O’Connor says.

“In traditional CAD, you start with a sketch, put it into a 3D profile, you insert parts from a file system and you keep drawing like that,” he adds. “We can do that, but with us, you can also drag-and-drop parts and assemblies from a catalog into the design environment, mesh the geometry, and use that for enhanced CAD design.”

Engineers do, of course, need to create the original file for the frequently used parts and assemblies, which are then stored in the catalog, from which they can be pulled from for use again and again.

“But engineers can use these parts confidently without worrying about how the original design was created,” O’Connor says.

The catalog of parts requires only one file, no matter how complex. Assembly part data is integrated into a file’s design rather than linking to external files, O’Connor says.

The CAD maker calls these cataloged parts “intelligent parts” because they contain the geometry and other information to fit the assembly seamlessly. The designer need not worry about that step.

This is what allows the drop-in and automatic fit, he adds.

“Rather than insert constraints to the part, we’re doing it on the fly, positioning and changing information at the same time. If you want to make it larger, the tool knows how to update the part to make that change,” O’Connor says.

The already-designed parts can be dropped within many popular CAD programs as well as into IronCAD designs, he says.

Some companies have integrated IronCAD software with their enterprise systems for even greater hands-off customization. Others have used it as a backbone of their own proprietary software. Still others use IronCAD as their design system.

Automation for quick customization

Take the example of Dutch company Van Keulen Interieubouw, which makes fixtures and equipment for retail and office environments, including shelving units and cashier stations made from materials like wood and laminate.

Customer needs vary according to the layout and the look they seek. The company can manufacture and customize almost any interior element to meet customer requirements. Van Keulen maintains manufacturing facilities for processing wood, metal, and plastic.

To stay ahead of competitors, the company delivers its products quickly after they receive an order, “Even going to the point to state if they need to deliver the next day, they will deliver the next day,” says Eddy Huis in’t Veld, the company’s software manager.

“To move from design to the finished products very fast, we have to be very flexible,” he says. “So, we have a high level of automation within our company.”

Using IronCAD, the company creates and stores the intelligent parts within its parts catalog. Some designs are reusable; others need quick modifications—easy to make on an already-created part where the CAD information also exists—and others need to be redesigned from scratch, Huis in’t Veld adds.

The parts can be added where needed to common CAD designs.

Engineers customize designs as they’re ordered, incorporating the pre-existing catalog of parts into their own design. The company has integrated the CAD application into its enterprise resource management system. When the engineer hits done, a parts request is automatically sent to the ERP system, which creates a list of needed parts for the manufacturing floor.

“ERP can extract the size, material technology, and many other aspects from the drawing,” Huis in’t Veld says. “It puts them into the production environment, sending them into the right machines in the right order.

“We can be in production within 15 minutes after the designer puts the drawing into the ERP system,” he adds. “Open your drawing, make the changes, and send it to ERP. With a few mouse clicks, we can start production again.”

In other words, designers can design a custom order and send it to the manufacturing floor within the same system.

“They’ve created a kind-of curated process-manufacturing system,” O’Connor says.

The design tool is also useful in the sales process, where salespeople can show potential customers how a potential shelving unit—for example—would look made from laminate, built to a certain size, and standing on particular types of legs. Suppose the customer seeks another shape for the legs, or would like a different style of shelving unit. In that case, a salesperson can make those changes quickly with IronCAD and present them immediately.

On the plant floor and in the race car

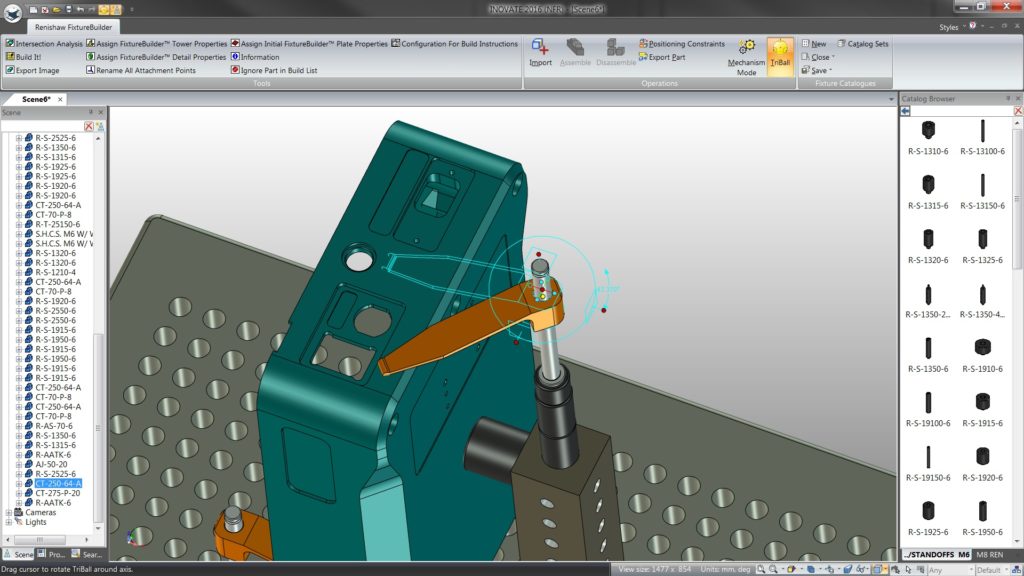

The drag-and-drop capability to customize parts and assemblies doesn’t stop with CAD itself. Software makers take IronCAD’s core functionality and build their own product around it. One example is Fixture Builder, a 3-D design and modeling product from Renishaw, a supplier of coordinate measuring machines and machine tools.

The software is used to create and document fixturing set-ups.

Fixture Builder’s fixtures have intelligence built-in because they’re made with and stored within the IronCAD’s design and catalog application.

“A designer would import the catalog model they want to build fixture around, drop the plate and components into their piece, and then the export file to show how someone in the real world would set up that fixture,” O’Connor says.

And of course, IronCAD is useful as a company’s primary modeling tool.

When mechanical engineer Andy Robinson opened his own business, he turned his love of drag-car racing, designing and building racecar chassis. And, while racecar drivers won’t be thinking of the software behind the design of their chassis, they’ll certainly appreciate its ability to hold its own in a roll.

While Robinson had long worked with CAD in previous roles, he knew for Robinson Race Cars, in Hampshire, England, he’d need a tool anyone on his team could use.

More importantly, he wanted an environment where they could manipulate, change, and alter designs in 3D easily and on the fly, Robinson says.

Soon, he knew that with the help of CAD technology his company could resupply car parts and design and build chassis.

For instance, CAD enabled Robinson’s team to take a single repair and develop a standard part, which he could stock and sell to all in the industry.

Today, many of the former touring cars featured in the British Touring Car Championship are now in the hands of private clubman racers and, as Robinson knew, those cars still got bent and broken most weekends. The owners—who couldn’t, of course, buy many vital parts off the shelf—had a hard time keeping their cars running.

The Kwik Fit British Touring Car Championship is a touring car racing series held each year in the United Kingdom. Touring cars are particularly suited to racing long distances.

Recently, one such racer came to Robinson Race Cars with a broken suspension upright from a Spanish SEAT touring racecar that needed repair. A common problem and one that possibly dozens of drivers were dealing with across Europe.

Using IronCAD, Andy was able to reverse engineer the part and create a 3D model for evaluation. He could then understand the structure of the upright and look for weaknesses in the original design. He then went to several machine shops for proposals.

Having created the part, Andy was then able to show it on his website and approach other SEAT race teams to offer them replacement uprights.

His love of drag racing got him into this business, and Robinson hopes he can turn his attention to supplying those parts as well. That’s certainly feasible. In 2010, many European countries began to wake up to the sport of drag racing, as abandoned airfields across Poland, Croatia, and Russian were converted into quarter-mile drag strips.

From its early days in the 1990s, configuration-based design has become a stalwart of the design process. While more and more CAD systems today include at least parts of the method, IronCAD first introduced the functionality with its release in 1998.

And users like Van Keulen and Renishaw continue to find new ways to put it to work for them.

IronCAD

www.ironcad.com