As an engineer, I often think about CAD as a tool for the engineering and design of technological products. But, every once in a while, I’m reminded that CAD can can be used in ways its makers never anticipated.

Shane McKenna is an engineer, designer, craftsman, and artist. I recently talked to Shane about how he uses CAD/CAM in his work, and he, as an aside, shared some of his art. Here’s what he said:

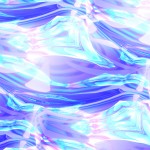

I always turn my tools to artistic endeavors sooner or later. It occurred to me that I could create abstract art by modeling shapes and then playing with the lighting, rendering and camera angles. I have not had a much time to play with these ideas lately, but would like to get them into a gallery at some point. I am open to doing commissioned pieces until I have created a large enough body of work to approach some galleries. These are all done in Solidworks.

If you like Shane’s work, you can contact him by email, at twoartistic@gmail.com.

Tomorrow, I’ll be following up, and posting an article about how Shane uses CAD, CAM, and 3D scanning in his (more conventional) work.

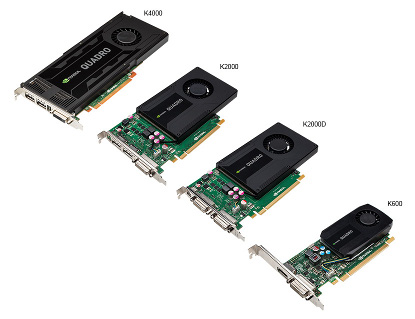

It’s taken awhile, but the new generation of NVIDIA GPU graphics cards are out.

It’s taken awhile, but the new generation of NVIDIA GPU graphics cards are out.