By Raymond Wodar, Global Business Consultant — CPG-Retail Industry • Dassault Systèmes

Most manufacturers know (or want to know) about the digital twin, which the Digital Twin Consortium defines as “a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.” The digital twin and its more comprehensive successor, the virtual twin, promise to make manufacturing more productive and less wasteful.

However, a virtual twin goes beyond digital continuity by representing a product or system as it exists in the present and the past. The past includes the traceability and history of the product or system’s design, testing, and manufacturing. The virtual twin also helps manufacturers simulate how a product will operate and must be maintained in the future.

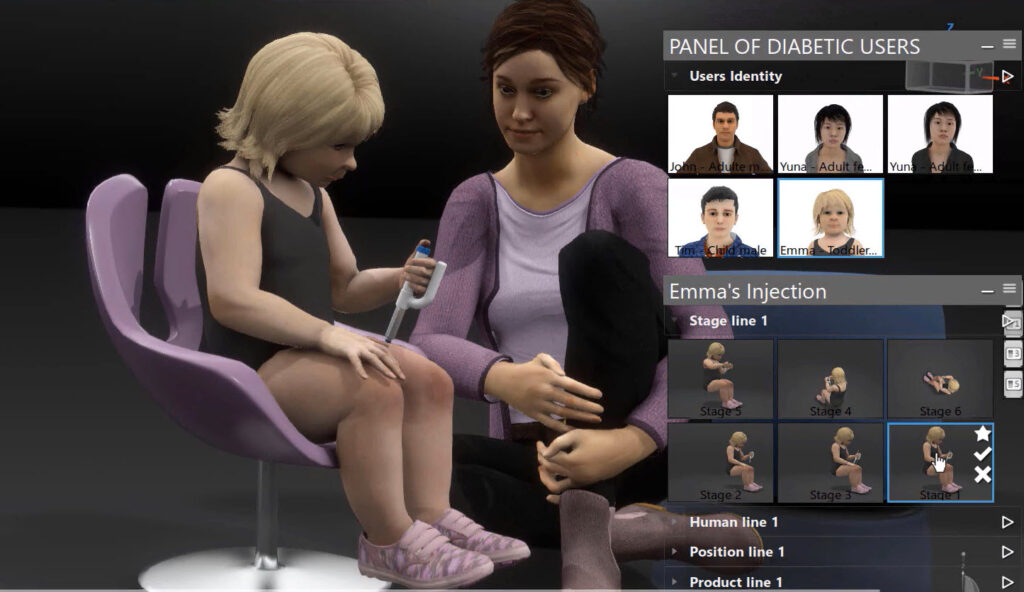

Virtual twins help companies develop complex systems and products with hundreds or even thousands of parts. By applying virtual twin technology to the design process in the transportation and mobility industry, for example, planes, trains, and electric cars not only have more advanced features but are safer and more fuel-efficient. Similarly, healthcare companies can ensure better patient outcomes, and city planners can improve infrastructure and the quality of life for citizens.

Consumer packaged goods companies increasingly leverage virtual twin technology to design and manufacture more sustainable food and beverage packaging. This technology helps packaging manufacturers fully assess tradeoffs between cost and eco-friendly designs, and it simulates decisions from materials to future recycling options before producing physical packaging.

Decisions made during initial design phases determine up to 80% of a product’s environmental impact, including a product’s packaging. According to estimates, only 9% of all plastics are recycled, and American consumers throw out nearly five pounds of trash each day — the majority of which is food and packaging. Thus, it’s easy to see the massive opportunity to improve sustainability. Manufacturers will play a significant role in the circular economy by creating durable products that are more easily repaired and recycled.

Consider Biopak of Australia and New Zealand. The company began producing compostable packaging from renewable plant-based materials to reduce the number of single-use takeout food plastic containers going to landfills each year. Similarly, New York-based Evocative Design harnesses the power of hemp hurds and mycelium (the root structure of mushrooms) to develop insulating, water-resistant packaging. Contrast the 500 years it takes Styrofoam to decompose with the “mushroom packaging” that composts in 45 days.

Leading manufacturers employ the virtual twin from the molecular level to the system level to achieve sustainable packaging. Plastic container giant Amcor began using advanced software simulation through virtual twins to lightweight their products, reducing the weight of its hot-fill beverage bottles by up to 50% and cutting consumption of thermoplastic polyethylene terephthalate (PET) by more than 100 million pounds annually.

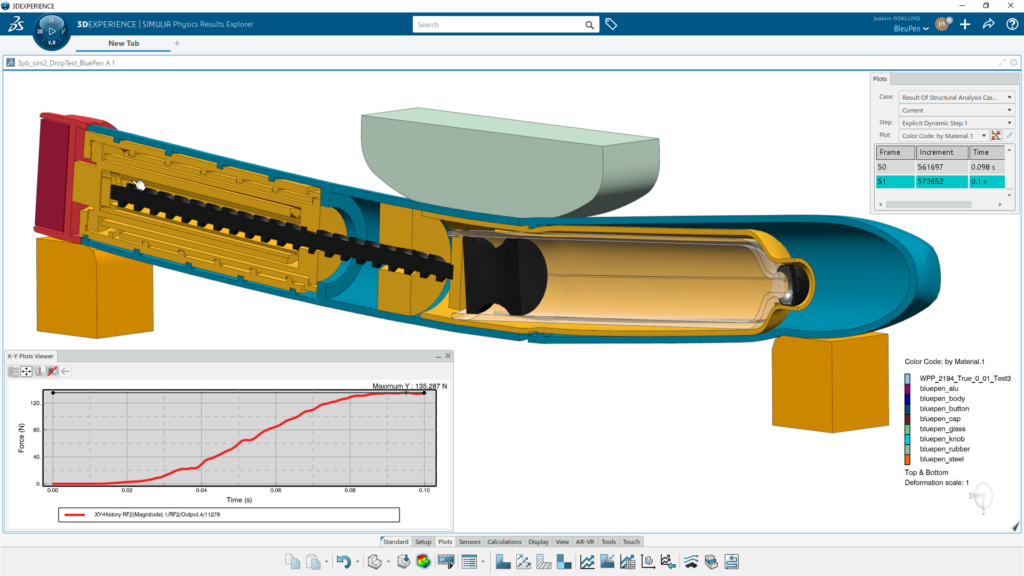

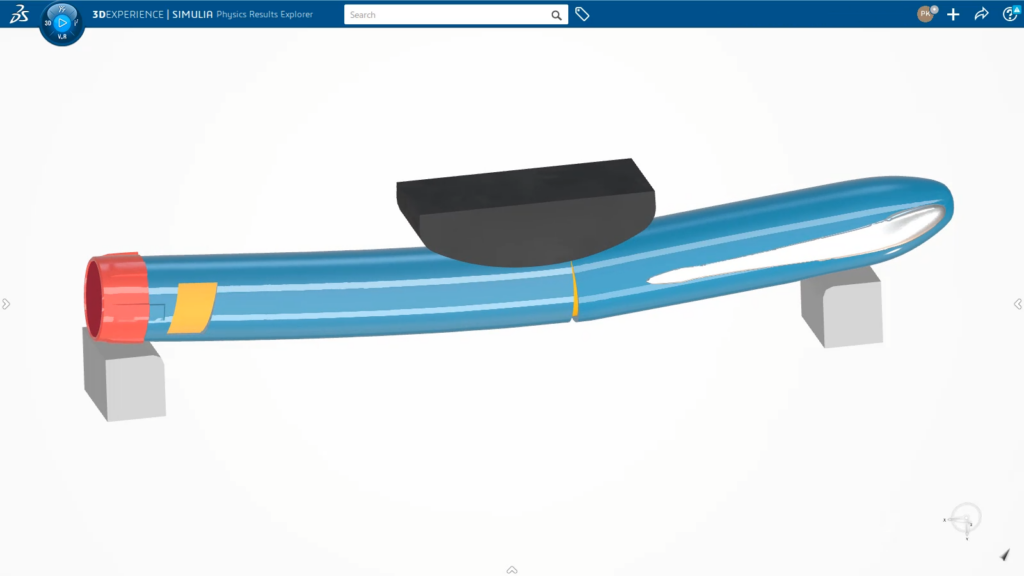

Like engineers developing an electric vehicle, Amcor’s packaging engineers applied these technologies to optimize the material placement and increase strength without adding weight. Running hundreds of simulations on a virtual 3D representation of a product reduced time and increased fidelity compared to testing physical prototypes, resulting in reduced development costs, project lead times, and waste.

The virtual twin goes much further than optimized box and bottle designs. A thorough and collaborative lifecycle assessment of a product in the early concept and design phase allows manufacturers to plan and validate its circular journey virtually before die-cutting or plastic injection molding begins.

Packaging designers can analyze which raw materials best suit the application. For example, by simulating the virtual twin of packaging for mushrooms, the designer or simulation analyst evaluates the optimal balance of cost, quality, performance, and recyclability to select the most sustainable option.

With validated packaging models in place, manufacturing virtual twins follow, which help packaging designers determine tooling investments, the optimal production floor layout, and workforce headcount well in advance. Using a virtual twin to simulate all processes and factory floor decisions not only saves significant financial costs but allows manufacturers to account for mistakes in the virtual world, which eliminate physical world mistakes and rework.

In addition, the virtual twin provides post-manufacturing visibility into last-mile delivery puzzles and solutions. Manufacturers can collaborate with logistics providers to optimize truckloads better and reduce instances of empty miles. Powerful algorithms applied to virtual twins help fine-tune shipping routes, adjust for traffic and workforce disruptions, and more. By optimizing logistics, companies can lower CO2 emissions while minimizing shipping and warehousing costs.

The competitive pressure to make products, services, and operations more sustainable aligns with providing the best possible customer experience. Approximately 88% of consumers in the U.S. and U.K. combined want manufacturers to invest in methods, processes, and technologies that improve their environmental and social footprint. Some estimates expect the value of the global sustainable packaging market to hit $255 billion by 2026. With the right tools in place, such as the virtual twin and a platform for future-ready operations, consumer packaged goods companies can enable sustainable operations and support the circular economy.

Dassault Systèmes

3ds.com