PTC announced that it has signed a definitive agreement to acquire Onshape, creators of Software as a Service (SaaS) product development platform that unites computer aided design (CAD) with data management and collaboration tools, for approximately $470 million, net of cash acquired.

The acquisition is expected to accelerate PTC’s ability to attract new customers with a SaaS-based product offering and position the company to capitalize on the inevitable industry transition to SaaS. Pending regulatory approval and satisfaction of other closing conditions, the transaction is expected to be completed in November 2019.

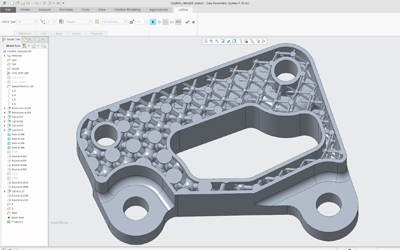

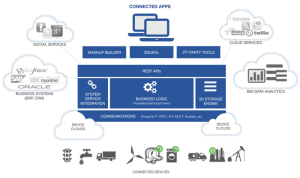

Located in Cambridge, MA, Onshape was founded in 2012 by CAD pioneers and tech legends, including Jon Hirschtick, John McEleney, and Dave Corcoran, inventors and former executives of SolidWorks. Onshape has secured more than $150 million in funding from leading venture capital firms and has more than 5,000 subscribers around the world. The company’s software offering is delivered in a SaaS model, making it accessible from any connected location or device, eliminating the need for costly hardware and administrative staff to maintain. Distributed and mobile teams of designers, engineers, and others can benefit from the product’s cloud nature, enabling them to improve collaboration and to dramatically reduce the time needed to bring new products to market – while simultaneously staying current with the latest software.

This acquisition is the logical next step in PTC’s overall evolution to a recurring revenue business model, the first step of which was the company’s transition to subscription licensing, completed in January 2019. The SaaS model, while nascent in the CAD and PLM market, is rapidly becoming industry best practice across most other software domains.

Onshape will operate as a business unit within PTC, with current management reporting directly to PTC President and CEO Jim Heppelmann.

Barclays acted as exclusive financial advisor to PTC on the transaction.

PTC

www.ptc.com