IronCAD introduces the first update for IRONCAD 2020, the latest release from a leader in design productivity of 3D CAD programs and preferred software of machine designers and engineers globally. The IRONCAD 2020 Product Update #1 (PU1) features enhancements and capabilities that enable IronCAD users to accelerate productivity and improve product development, from conceptual design to manufactured products, and create value for their organizations.

Designed with a focus on performance, quality improvements, and design productivity, IronCAD’s research and development team delivered IRONCAD 2020 PU1 in response to enhancement requests from the IronCAD community around the world. With the many new capabilities and enhancements in PU1, users can benefit from an array of options and opportunities to improve system performance in their daily operations, streamline workflows and seek new levels of collaboration and agility to more quickly and cost-effectively deliver products to their customers.

Among the many new improvements and capabilities in IRONCAD 2020 Product Update #1 are:

–Open/Save/Import Performance: Continued improvements have been performed in this area to reduce the load/save times of extremely large assembly data sets to improve the overall performance when designing with large assembly files.

–IronCAD Drawing (ICD) View Creation/Update – Improvements have been made to improve the view creation and view update speed in the drawing environment, especially with large assembly files.

–IronCAD Drawing (ICD) View Camera Performance – New options to control functions additional performance settings have been added to aid in the overall camera interaction performance when interacting and detailing drawings.

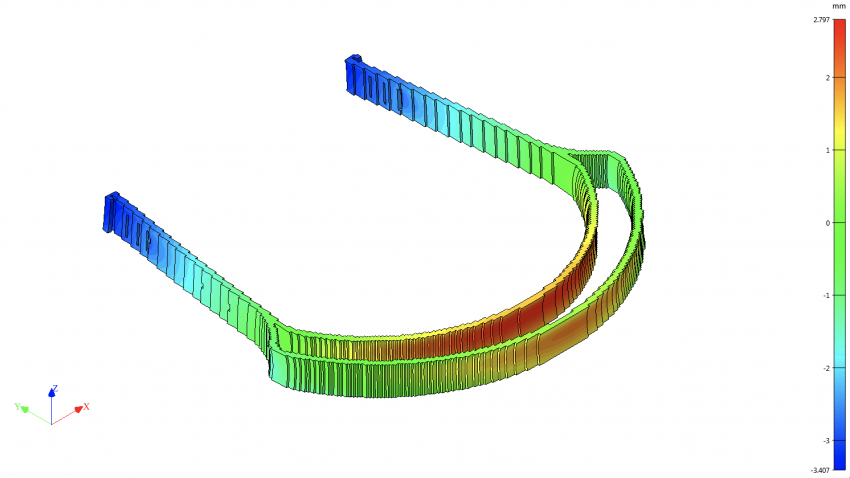

Further improvements within Product Update #1 also include enhanced general quality improvements to the 2D Technical Drawing Area. Aligned with IronCAD’s position as a productivity leader for CAD software, PU1 also boasts improvements to the Bulk View Creation for automated drawing creation, including new search capabilities and creation from a selected set of parts/assemblies. Additional productivity improvements in PU1 improve the Sheet metal capabilities for Out/In Bend Automatic alignment to the angled stock, Quick Access commands added to right-click menus to improve speed and visibility in accessing commands as well as improvements to now create singled drawing sheets quickly from the selected elements in the scene.

IronCAD

www.ironcad.com/whatsnew

www.ironcad.com/free-online-trial