Siemens claims it’s latest version of NX software delivers the next generation of design, simulation and manufacturing solutions that enable users to realize the value of the digital twin in the end-to-end process.

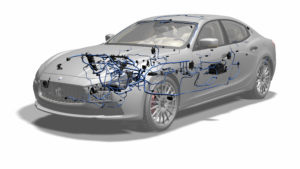

This latest release unites electrical, mechanical and control systems through close integration with Mentor Graphics Capital and Xpedition portfolios for electrical systems, harness and PCB design.

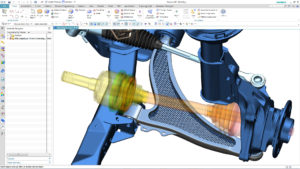

NX underpins tools used for systems driven product development based on the RFLP (Requirements, Functional, Logical and Physical) methodology, which provides a significant connection between the logical and physical abstractions in both electrical and mechanical domains. Building on Convergent Modeling technology that lets designers seamlessly work and model with mesh geometry in combination with precise geometry, the new version combines tools for design optimization, advanced geometry creation, freeform shapes and parametric design to make generative design a reality.

As electronics become essential to all products, regardless of industry, it’s important that electrical and mechanical designers collaborate throughout the product development process. Using technology from recently acquired Mentor Graphics, the latest version of NX provides a direct connection between the design of electrical and mechanical systems. Linking the electrical tools and the 3D model, enables co-design including cross-probing, allowing designers of wiring diagrams and harnesses to work closely together, preventing costly and time-consuming rework due to electromechanical issues.

Multidisciplinary work is not limited to electrical design. Industries involving large amounts of piping, such as ship building, will benefit from close integration between instrumentation diagrams and 2D schematic layouts. New tools in NX allow engineers to lay out piping and instrumentation diagrams in two dimensions, while maintaining the design tied to the 3D space model. This synchronization can help eliminate errors and save time as teams work more closely than ever before.

With increasing pressure to deliver products to market more quickly, generative design integrates a variety of tools to give designers more flexibility and choice when dealing with complex geometries. Using these technologies in combination also allows companies to go beyond traditional solutions that focus solely on optimizing shape to achieve multidisciplinary design.

In the constant drive to reduce component weight and improve resource usage, companies are looking to incorporate lattice structures into design to meet these goals without compromising on strength and structural integrity. The latest version of NX delivers new approaches to design for additive manufacturing, including the ability to add lattice. Convergent Modeling makes it possible to work directly with faceted geometry such as these lattice structures, saving companies from the lengthy data conversion process normally required. This enables companies to deliver lighter, stronger products to market in much less time.

“The fact that the faceted geometry now comes in as a convergent body and behaves pretty much as a sheet or solid body is beneficial. It will make our workflow more efficient and save time that we can spend on other things, such as more projects,” added Jonas Brochman, engineering method specialist of Manufacturing Engineering, GKN Aerospace Engine Systems, Sweden. “The ability to associatively compensate and reposition the faceted scan data of hardware in an associative and controlled way will greatly help us to increase efficiency and resulting quality.”

Siemens PLM Software

www.siemens.com/plm

Leave a Reply

You must be logged in to post a comment.