PTC announced that in an extensive benchmark process Aston Martin Racing selected and implemented Creo Elements/Pro for the 3D CAD design of its racing vehicles and Windchill for product lifecycle management (PLM) in its race car division.

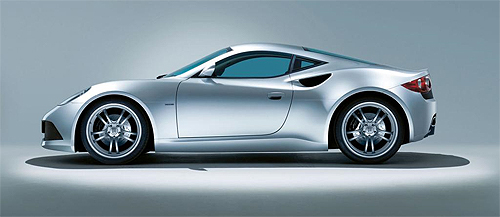

Aston Martin is the only manufacturer that produces a car to compete in every category of the FIA GT Championship sports car racing series. Models range from modified standard vehicles in the GT4, GT3 and GT2 classes – including the high-performance V12 – to the 6.0 litre 600 BHP DBR9 in the GT1 class and the Le Mans prototype LMP1 Aston Martin.

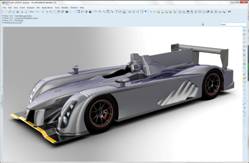

Aston Martin Racing has moved away from its previous third-party chassis strategy to develop its next generation LMP1 from scratch. This new racing vehicle is now being designed and engineered from the ground up using Creo Elements/Pro and Windchill to manage the development process. In addition to the designers, the purchasing department uses Windchill for its request for quotation process, enabling collaboration with suppliers.

PTC

www.ptc.com