Software manufacturer CoreTechnologie has entered into a partnership with printer specialist Weirather to realize an open system for SLS 3D printing of high-quality plastic parts. With the new application, the user works in the 4D_Additive software seamlessly from the CAD model until the dispatch to the Weirather printer.

Full control and flexibility

In the Build Manager of the new software version, all slicer settings and laser parameters can be freely adjusted beyond the predefined parameter sets. The user thus has the full control and flexibility of an open system. The software has a modern, fast, and easy-to-use graphic interface and innovative features such as automatic 3D nesting with optimal heat distribution.

The open 4D_Additive SLS and SLM Build Manager provide access to all slicing parameters. Laser speeds, hatching strategies, and path distances for contour, hatching, upskin and downskin, and laser and Z-compensation can be adjusted by the user beyond the standard settings and optimized for other materials.

The individual layers of the print job, so-called slices, are simply stored on the Weirather machine via the network in a standard svg format. This ensures optimal traceability and transparency of the workflow. After saving the packed slices in wls format, the jobs are visible in the printer’s job list and can be started immediately. Moreover, the integration does not require an internet connection of the printer or a print server and is thus completely self-sufficient.

Seamless process

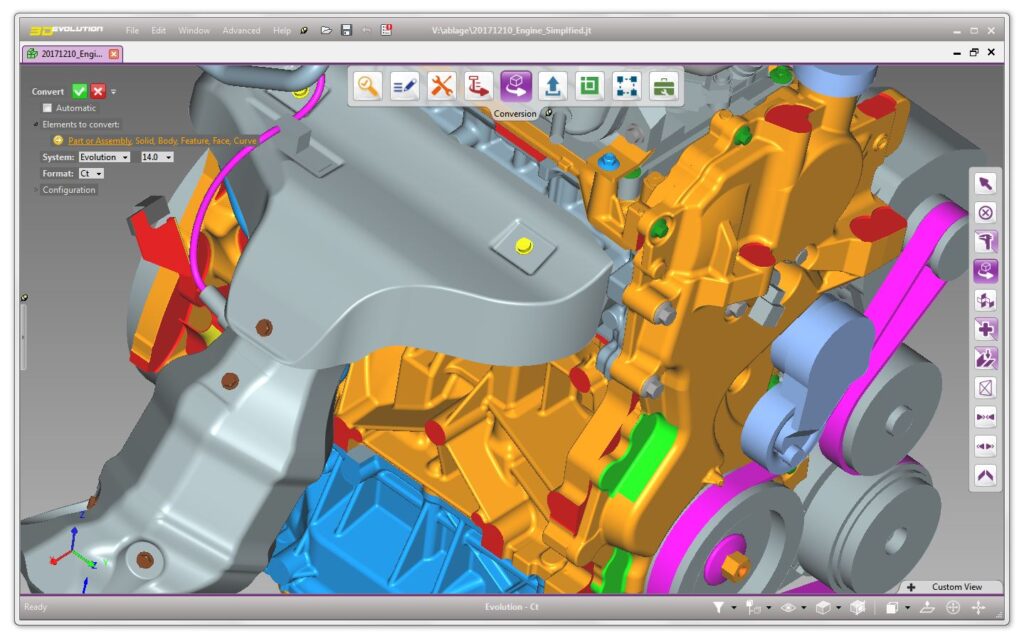

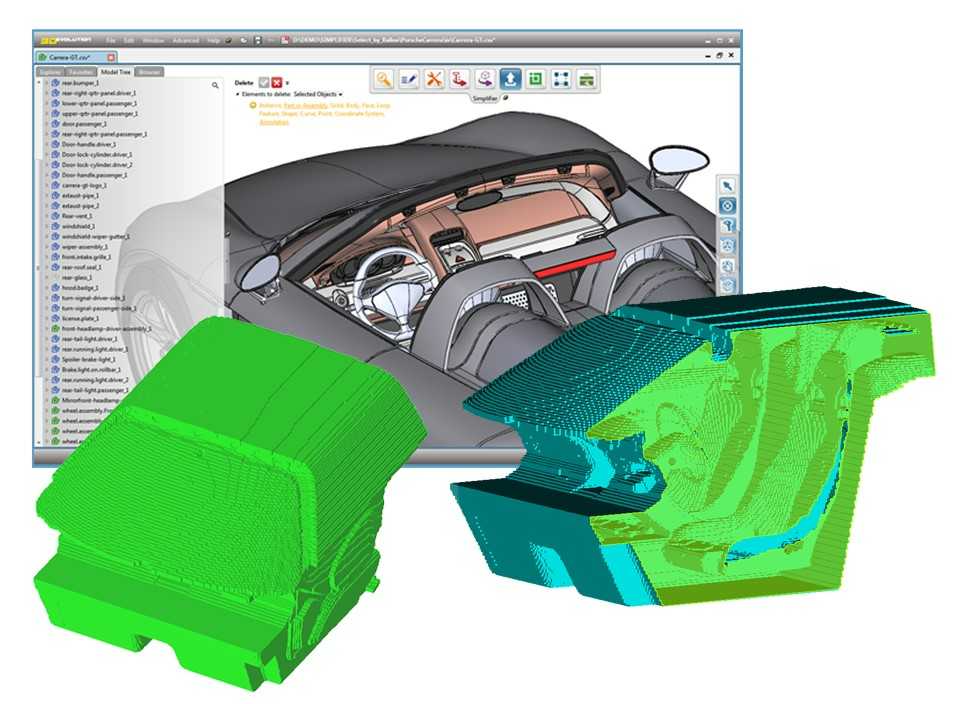

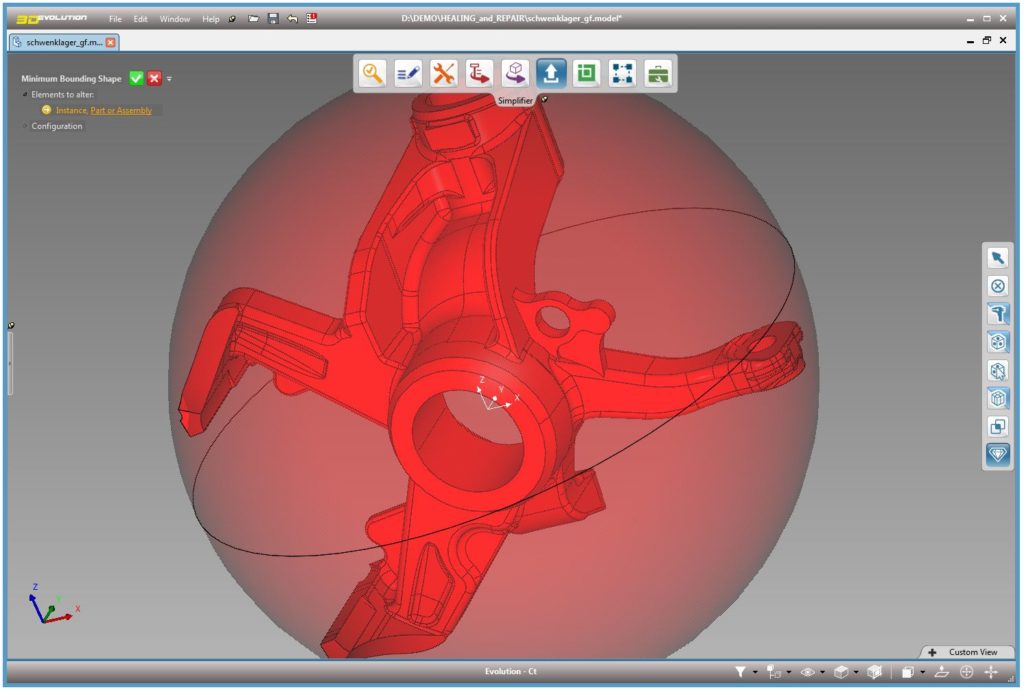

With the 4D_Additive software, for the first time it is possible to accurately check, repair, and prepare print jobs according to CAD engineering standards based on the original CAD geometry. The software reads all common native and standard formats and processes CAD data as well as STL models with the hybrid core. The new tool covers the entire process from CAD model to the 3D printer. The software’s native interfaces avoid additional generation of STL data in the CAD system. The exact, lightweight 3D data are also used for nesting and allow a very compact description of the print job.

Extensive application possibilities

The open and independent technology enables quick adaptations, such as for new materials. A current example is Weirather’s optimiazation of the printing of polypropylene materials especially for the medical sector and the food industry, which was realized in just a few days.

CoreTechnologie

coretechnologie.com