“This is why we test.” It was one of the comments to a YouTube video, showing a dramatic rear suspension failure while running a braking test on a Force Protection MRAP vehicle. Another comment pointed out that this was a first generation design, which had been greatly improved since the test.

When I saw the video, my first thought was that this was an example of aspirational engineering. That’s a polite way of saying “crossing your fingers, and hoping it will work,” rather than doing the up-front engineering to prove it will.

Don’t take what I’m saying wrong. Sometimes, the best way to engineer something is to not engineer it. If I were designing a suspension system for an MRAP, the first thing I’d do would be to look for commercially available alternatives that have already been engineered (such as, for example, the TAK-4 independent suspension, from Oshkosh.)

But, assuming I was in the position of needing to actually engineer the suspension, I don’t think I’d just draw it up, and hope it worked. I think I’d want to develop a practical and reliably replicable process, incorporating systems engineering and simulation, to gain confidence that, as a start, I was on the right conceptual track, and that the suspension would perform as designed—before manufacturing costs were incurred. And before warfighters were put in harm’s way by its potential failure.

Some defense contractors may not think this way (though, to be fair, MRAPs were rushed into the field with less engineering than typical, because our soldiers were facing IEDs with Hummvees—with fatal results.) Yet, the DoD Systems Engineering Research Center definitely thinks this way: Systems 2020 is their strategic initiative to transition the design, adaptation and manufacture of defense systems to “twenty-first century engineering practices and tools.”

Ever since I read the Systems 2020 report a couple of years ago, I’ve been mulling over this concept of bringing together the disparate processes used by engineers within their particular segments of the overall product development process. I’ve seen flashes of technologies that fit into this realm: Active Workspace, from Siemens PLM, Comet Workspace, from Comet Solutions, ModeFrontier, from Esteco. None of these are really PLM. They’re part of something beyond PLM. Something that doesn’t really have a name.

Or, maybe it does?

Last week, I got a note from Bruce Jenkins, of Ora Research. He’d read something I’d written on the importance of systems engineering, and asked the question “Why is it not more evident to everybody?”

Looking at the Ora Research website, I found Bruce’s discussion of design space exploration (DSE):

The most successful engineering projects begin with discovery – conceiving a rich array of ideas to solve a problem or address a need. But the power of such discovery is too often sacrificed to schedule pressures and resource constraints. Add to these the toolset barriers and hamstrung work processes that make it a struggle for discipline experts to look beyond their own silos and work more collaboratively as a team – to achieve the critical but elusive goal of gaining a system-level understanding of the project and their role in it, then acting on it. The result is familiar: engineering teams find themselves forced to settle on a design concept without high confidence that it’s the best, most cost-effective or most robust choice.

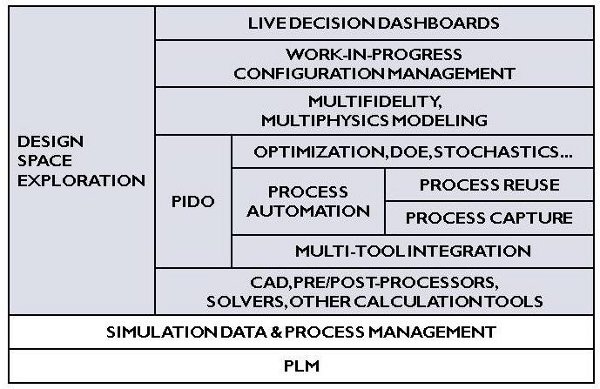

An emerging solution to this quandary is design space exploration (DSE), both a category of methods and a new generation of software tools that are beginning to radically advance the capabilities of engineers and multidisciplinary engineering teams to discover an array of possible design concepts early; rapidly and fluently evaluate tradeoffs, variants and sensitivities; then select the best and move to implement them.

This is the first time I’ve seen these multiple disciplines grouped together in such a cogent fashion. I think Bruce may have something here.

If you’re interested in twenty-first century engineering practices and tools, I recommend downloading the prospectus for Ora Research’s report on Design Space Exploration.