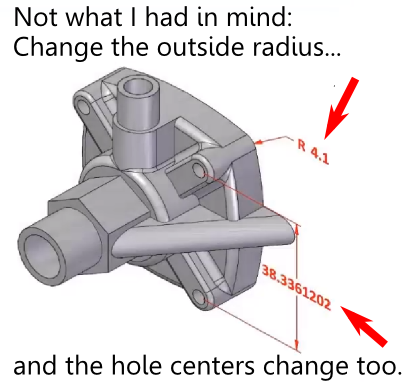

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.

It’s a lot more difficult than it ought to be, for a variety of reasons. Several months back, I wrote a series of articles discussing those reasons, as well as some of the solutions that have come up over the years. What was missing from the series was a final chapter; a detailed description of what could prove to be a viable solution to problems with model reuse: the resilient modeling strategy.

The resilient modeling strategy (RMS) is the brainchild of Richard “Dick” Gebhard. I wrote about Dick last June, in the article A Resilient Modeling Strategy. He’s a low-key guy with deep experience and serious expertise in the practical use of MCAD software. Over his career in CAD, he’s been a reseller for CADKEY, Pro/E, and most recently, Solid Edge.

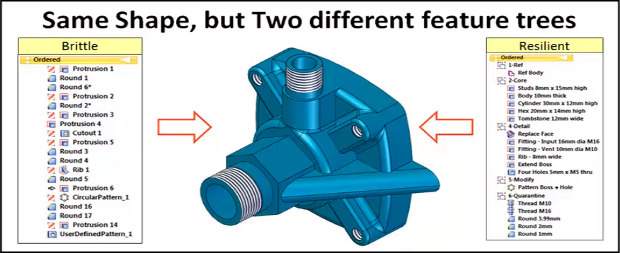

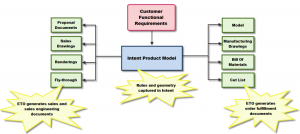

RMS is a best practice for creating CAD models that are stable and easily reusable (even by inexperienced users.) It can be learned and easily used by typical CAD users, it preserves design intent in models, and provides a mechanism by which managers or checkers can quickly validate a model’s quality.

When Dick first started thinking about the concepts that make up the resilient modeling strategy, it was natural that it was in the context of showing the advantages of Synchronous Technology (The Siemens PLM brand name for its version of direct modeling.) In our discussions about RMS over the last year or so, I pointed out that, while I thought that RMS did indeed demonstrate the benefits of hybrid history/direct modeling in Solid Edge, for it to be taken seriously, and not be unfairly dismissed as a marketing initiative for Solid Edge, it needed to work with a wide variety of MCAD tools. I think Dick got where I was coming from, because he’s continued to refine and generalize RMS, with feedback from users of a number of MCAD systems.

In its current incarnation, RMS works particularly well with Solid Edge, as might be expected, but also works very well with Creo, NX, CATIA, and IronCAD (all of which are hybrid history/direct systems.) Further, with a few modifications, it can provide compelling value with SolidWorks, Inventor, and Pro/E (all of which are primarily history-oriented systems.)

It’s significant that RMS is also free to use. While Dick is available to provide presentations, seminars, and training, he has not attempted to patent, or keep as trade secrets, the underlying concepts of RMS. (He does claim a trademark on the term “Resilient Modeling Strategy,” which means that organizations offering commercial training on RMS will need to get Dick’s OK to use the term.)

Dick has posted an introductory presentation on RMS at resilientmodeling.com. While the entire presentation is 20 minutes long, the first 3-1/2 minutes cover the problems that people invariably experience when reusing or editing history-based CAD models. Watching that much will likely convince you to watch the rest.

On Wednesday, November 20, at 10:00 AM PST, Dick will be hosting a webinar on RMS. It’s scheduled to last just 30 minutes, with the emphasis on content, not hype. If you’re a serious CAD user or a CAD manager (or, for that matter, you work for an MCAD developer), it’ll be well worth your time to attend.

TL;DR: Resilient Modeling Strategy is a best practice for creating high quality reusable 3D MCAD models. It works with many CAD systems, it’s easy to learn and use, and it’s free. Big payoff for MCAD users.

Presentation at resilientmodeling.com

Register for Nov 20 webinar on Resilient Modeling

I open up Creo Parametric, and load up a part model. Not too complex — some bosses, holes, and a bunch of blends. I select a blend (or “round,” to use PTC parlance), then click and drag its resizing handle. And wait. And wait. Eventually, after several seconds, the blend resizes. I wait some more, and the blend resizes again. Ad nauseum.

I open up Creo Parametric, and load up a part model. Not too complex — some bosses, holes, and a bunch of blends. I select a blend (or “round,” to use PTC parlance), then click and drag its resizing handle. And wait. And wait. Eventually, after several seconds, the blend resizes. I wait some more, and the blend resizes again. Ad nauseum. PTC will soon be releasing Creo 2.0, and, in anticipation of this, invited me (along with three other blogger/editors) to their corporate headquarters for a preview. Unlike a formal release presentation, which would be heavily scripted, our experience was much more extemporaneous. We got to see a good chunk of what’s new, hear about PTC’s underlying goals, and even talk about things we thought they should be doing better.

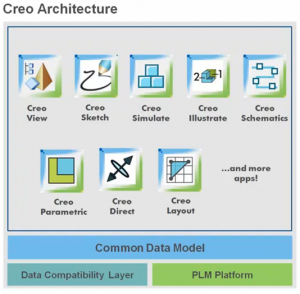

PTC will soon be releasing Creo 2.0, and, in anticipation of this, invited me (along with three other blogger/editors) to their corporate headquarters for a preview. Unlike a formal release presentation, which would be heavily scripted, our experience was much more extemporaneous. We got to see a good chunk of what’s new, hear about PTC’s underlying goals, and even talk about things we thought they should be doing better. What to do? How to rationalize these seemingly irreconcilable things? The only reasonable answer is to offer customers what they want. For PTC, this required a new strategy: Offer a range of products sharing a common data model and a common user interface design, and allow users to choose whether they want to use history-based, direct, or any other form of modeling that might come along in the future.

What to do? How to rationalize these seemingly irreconcilable things? The only reasonable answer is to offer customers what they want. For PTC, this required a new strategy: Offer a range of products sharing a common data model and a common user interface design, and allow users to choose whether they want to use history-based, direct, or any other form of modeling that might come along in the future.

Two years ago, at SolidWorks World (the show) SolidWorks (the company) showed what appeared to be the next generation of SolidWorks (the software): SolidWorks V6 (also software.)

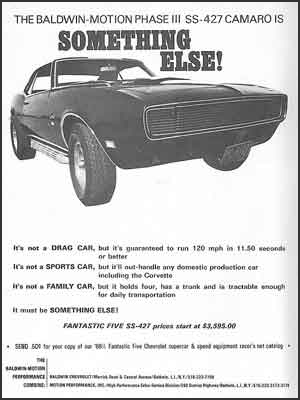

Two years ago, at SolidWorks World (the show) SolidWorks (the company) showed what appeared to be the next generation of SolidWorks (the software): SolidWorks V6 (also software.) When I was barely a teenager, in the early ’70s. I became interested in car magazines. In the back of some of those magazines, I’d often see ads for a company called Baldwin/Motion Performance. They sold brand new hot-rodded Camaros that were guaranteed to run 11.50 second or faster quarter miles at the drag strip. Baldwin/Motion Performance Camaros represented the epitome of tuner-built hot rods. They were fast enough that, according to Super Chevy magazine, you could buy one, and, with no further tuning, win the A/MP class at the Winternationals.

When I was barely a teenager, in the early ’70s. I became interested in car magazines. In the back of some of those magazines, I’d often see ads for a company called Baldwin/Motion Performance. They sold brand new hot-rodded Camaros that were guaranteed to run 11.50 second or faster quarter miles at the drag strip. Baldwin/Motion Performance Camaros represented the epitome of tuner-built hot rods. They were fast enough that, according to Super Chevy magazine, you could buy one, and, with no further tuning, win the A/MP class at the Winternationals. There’s no doubt that the Z1 costs more than a typical commodity PC. But, for people doing serious CAD, CAE, or CAM work, the performance and reliability the system offers is worth the premium.

There’s no doubt that the Z1 costs more than a typical commodity PC. But, for people doing serious CAD, CAE, or CAM work, the performance and reliability the system offers is worth the premium. BOXX doesn’t really like to use the work “overclock,” because it implies that they’re pushing the processor past it’s design spec. BOXX works closely with Intel, to make sure they stay within the processor design specs. Since they use liquid-cooling, they can push the processor faster, without reliability problems. Their workstations are backed-up by a 3 year warranty, and, in their history of selling overclocked systems, they’ve never experienced a processor failure.

BOXX doesn’t really like to use the work “overclock,” because it implies that they’re pushing the processor past it’s design spec. BOXX works closely with Intel, to make sure they stay within the processor design specs. Since they use liquid-cooling, they can push the processor faster, without reliability problems. Their workstations are backed-up by a 3 year warranty, and, in their history of selling overclocked systems, they’ve never experienced a processor failure.