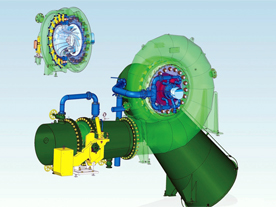

The Flovel Group is a hydropower equipment supplier that provides turnkey solutions for small- and medium-sized hydropower projects. Business units include Flovel Energy Pvt. Ltd., which specializes in the entire range of hydropower equipment and services for design, engineering, manufacturing, installation, and servicing for all heads and outputs covering all types of turbines, and TB Hydro Flovel Valves Pvt. Ltd., which designs and manufactures a variety of inlet, shut-off, regulating, and air valves for turbines.

At one point, Flovel’s management began to look for product development technology that was adept at accelerating the release of highly customized, innovative new products to market, while at the same time being able to ensure the high quality and rigorous accuracy required by its customer base.

To meets its requirements, Flovel selected products from Siemens PLM Software including Solid Edge, Teamcenter Express, NX, and Femap with NX Nastran. Solid Edge is used for CAD to design complex turbine parts. Flovel based this decision on the software’s ability to handle sophisticated designs, 2D functionality, and sheet metal handling capabilities. Based on the successful use of Solid Edge at Flovel, the company is looking to leverage the product in other areas, including CAE, CAM, and product lifecycle management (PLM).

Using Solid Edge, Flovel has improved its overall design methodology (concept to prototype to product) and cut costs (due to a better understanding of 3D conceptual prototypes). The company cites outstanding ease of use compared to traditional approaches to design, noting that the user-friendly Solid Edge is fostering idea generation and innovation. Flovel also gives Solid Edge praise for superior searching options for making assemblies and points out that the visualization capabilities of Solid Edge measurably accelerates the handling of large assemblies.

Once Solid Edge was in place, Flovel implemented the second step in its product development initiative by adopting Teamcenter Express as its collaborative product data management (cPDM) solution. The goal was to establish a scalable cPDM solution that would facilitate collaboration between all of the key disciplines in the company’s product development operations. The procurement team selected Teamcenter Express for its visualization and collaboration capabilities, strong multi-CAD and multi-site support capabilities, and the ability to streamline the company’s design process. With Teamcenter Express, the company wanted its planning, design, engineering, and production departments to establish a synchronized engineering database with design information that users could easily access, share, and exchange on a secure and controlled basis.

Other goals for Teamcenter Express included establishing drawing number controls and materials codes, identifying the latest versions of their design information, and disseminating information in standard workflow-driven design processes. The company wanted standard, up-to-date information, such as what is contained in product catalogs, quality standards, manuals and plans, to be kept in Teamcenter Express for immediate access. Beyond this, Flovel engaged Teamcenter Express to manage released design information so that it can be leveraged by all of the company’s business units and their manufacturing operations for purposes of improving its CAM and CNC machining processes.

Flovel has extended its design process capabilities by implementing NX which is enabling designers to model difficult surfaces such as runner blades more easily. The company has also implemented Femap with NX Nastran. The intent of this deployment is CAE design optimization.

Currently, Flovel is using Femap with NX Nastran to analyze complex components. The company is performing finite element analysis (FEA) on turbine components for customized applications and operating conditions, as well as using the software to verify designs developed using conventional design tools. In addition, Flovel plans to extend its use of Teamcenter Express to other organizations and integrate the company’s enterprise resource planning (ERP) system into its product development initiative.

Siemens PLM Software

Flovel

www.flovel.com