My friend Rachael Dalton-Taggart, Director of Marketing Communications at Geomagic Solutions (which is now part of 3D Systems), often has interesting perspectives on the engineering software market. Every once in a while, she’ll start an email thread on some intriguing or irritating issue, and include a bunch of industry editors/anaysts/consultants in the distribution list (we all know each other, from attending shows and conferences over the years.) These email threads end up being rather like a “sitting by the pool at COFES” conversation, where we get to rant a bit, knowing that the people who are listening actually have the background to get what we’re saying.

My friend Rachael Dalton-Taggart, Director of Marketing Communications at Geomagic Solutions (which is now part of 3D Systems), often has interesting perspectives on the engineering software market. Every once in a while, she’ll start an email thread on some intriguing or irritating issue, and include a bunch of industry editors/anaysts/consultants in the distribution list (we all know each other, from attending shows and conferences over the years.) These email threads end up being rather like a “sitting by the pool at COFES” conversation, where we get to rant a bit, knowing that the people who are listening actually have the background to get what we’re saying.

Yesterday, Rachael dropped me an email, about an application story she’d gotten from Mecsoft. Here’s what she said (with my short comments interspersed in [square brackets]):

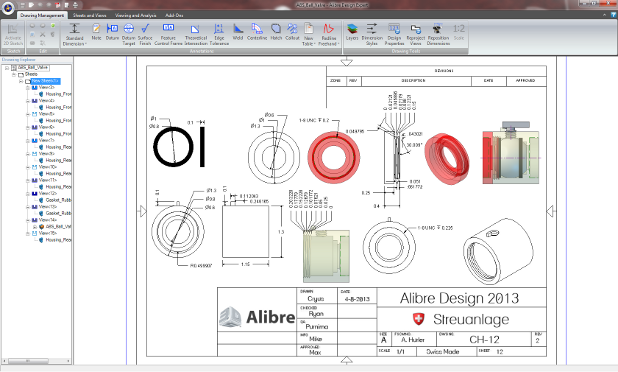

“I’m not sure if you would even be interested in this customer case study but I got this from MecSoft, about use of Geomagic Design [formerly Alibre Design] with ‘Alibre CAM.’ It’s a nice story. What intrigues me is that after the last ten years of people like you, me, Martyn [mutual friend of Rachael and myself, industry gadfly, and founder of Develop3D] etc discussing how ‘everyone’ already has cad, there are times when that is obviously not the case and this is one.

The more I dig into manufacturing operations, the more I see some realities that are seldom talked about: People coming here [to Geomagic] for training in inspection software who can barely turn on a computer. (Yes, they use a ruler and calipers to inspect their products.) Companies still on 2D CAD – exclusively. We have been spoiled with the ‘top end’ stories such as Boeing, Ford and the like who spend millions on interop and enterprise-wide CAD.

Is she ever right. I spend a lot of my time looking at top-end applications, often working my tail off to understand the nuances of their technology. Yet, innumerable companies (much less, individual engineers and designers) are nowhere near being able to afford these tools. For them, moving from using a 2D CAD program such as AutoCAD LT to a relatively inexpensive 3D MCAD program such as Alibre (which was not-too-long-ago acquired by 3D Systems, and rechristened “Geomagic Design”) can be a really big deal.

Though I try to cover a broad spectrum of engineering software tools, I get more personal satisfaction out of talking about tools that empower individual engineers and designers than I do talking about tools that empower enterprises.

So, thank you, Rachael. You’re right—this is a nice story. And thank you, Mecsoft, for recognizing that simple CAD/CAM tools that don’t cost an arm and a leg can make a big difference for small businesses.

Here is the case study, written by Tim Strifler of Mecsoft, telling how one of their customers used Geomagic Design and Alibre CAM to transform his business. Again, I’ve interspersed my comments in [square brackets]:

Alibre CAM: Changing Businesses, One Shop at a Time

By Tim Strifler, Marketing Coordinator, Mecsoft

Not to toot our own horn, but we hear success stories all the time about how our customers have utilized our software in effective ways and how it’s helped their businesses. But our benchmark for a truly satisfied customer changed after speaking to Chris Milligan of CRM Fabrication & Repair. Chris began to tell us how our software has “literally changed his business” and that Alibre CAM has “brought his manufacturing capacity into the 21st century.” Let’s back up and see what lead to Chris’ success with MecSoft CAM software.

CRM Fabrication & Repair is a small family-owned fabrication and machine shop located in the hills of Northeast Georgia. Chris told us their story is one of humble beginnings and hard work. He started the company in Longview, Texas, with only a stick welder and a 1978 Ford truck. Their drawings were constructed on graph paper or on the floor with soapstone. Eventually they were able to get their hands on a student copy of AutoCAD 2D. At that time, their services were limited to what could be welded with a DC stick or TIG welding machine, or items that could be brazed with an acetylene torch rig. Fast-forward through 15 years and a relocation to Georgia, CRM Fabrication & Repair now has four full time employees, upgraded equipment and machinery, and a full machine shop. This includes a recently purchased CNC machining center and a vertical machining center.

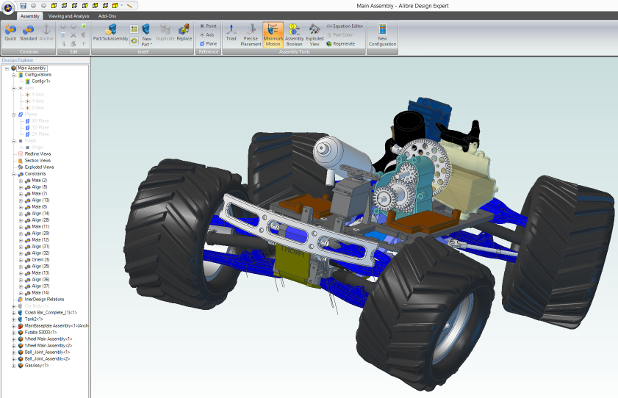

[I think we all know people like this, who start with basic tools and raw talent, and build it into a solid business, with rabidly loyal customers. One of my favorite examples is Industrial Chassis, in Phoenix. They’re fabricators at heart, and use Alibre to design everything from fixtures, to stamping dies, to metal forming machinery.]

CRM Fabrication & Repair, of course, has also purchased a seat of both Geomagic Design (formerly Alibre Design) and Alibre CAM 3, which, in the words of Chris, has “transformed their business.”

Wheel Finishing Stand

Over 10 years ago a company approached CRM Fabrication & Repair with a unique product request. The company specialized in refinishing car wheels, and they wanted a stand that would assist in this process. Of course this was before CRM Fabrication had embraced CNC and CAD/CAM software, so creating a unique product was a little more difficult. They were able to complete the product and ship the order, but it wasn’t pretty, and it wasn’t done efficiently. It was bittersweet when the customer would come back year after year and order more.

Over 10 years ago a company approached CRM Fabrication & Repair with a unique product request. The company specialized in refinishing car wheels, and they wanted a stand that would assist in this process. Of course this was before CRM Fabrication had embraced CNC and CAD/CAM software, so creating a unique product was a little more difficult. They were able to complete the product and ship the order, but it wasn’t pretty, and it wasn’t done efficiently. It was bittersweet when the customer would come back year after year and order more.

Chris was happy to have satisfied the customer’s needs, but hated producing them. “I never had the software to build them right or build them profitably.” Still, word got around to other auto shops about these handy wheel stands, and Chris received more and more orders.

He eventually had the right software (Geomagic Design + Alibre CAM), and it was time for a redesign! The drawing went from a lunch break napkin to a full CAD model in four or five hours. Thanks to Geomagic Design and Alibre CAM, the product has a more refined design, which allows it to be adjustable, and makes it less expensive to ship. According to Chris, the retail cost for the completed modular units (fully powder coated) is 15% cheaper than the “crudely built units that originally spawned the idea 10 years ago.” This, of course, results in higher profit margins for CRM, too.

[My guess is that improved profits from this redesigned wheel finishing stand will ultimately more than offset the cost of Geomagic Design and Alibre CAM. So, a half-day’s use of the software justified the investment.]

CRM Fabrication & Repair: www.crmfabrication.com.

MecSoft Alibre CAM: www.mecsoft.com/alibre-cam or call 949.654.8163.

3D Systems Geomagic Design: www.alibre.com

Another perspective

I believe that relatively low-cost workman-like CAD and CAM tools are an important segment of the engineering software industry. CRM gets tremendous benefit from using Geomagic Design and Alibre CAM, without even coming close to pushing the capabilities of the products. But its owner, Chris, never would have known what was possible had he been put-off by the initial price of the software (whether or not he could technically afford it.)

Yet, it’s important to keep things in perspective: cost is not everything.

There may come a day when Chris adds a few new machines to his shop. Maybe a 5-axis machining center, a Mill-Turn, or a waterjet? When you have a couple of hundred thousand dollars or more wrapped up in machines, the economics of CAD/CAM software change. Improved capabilities and productivity outweigh initial cost considerations.

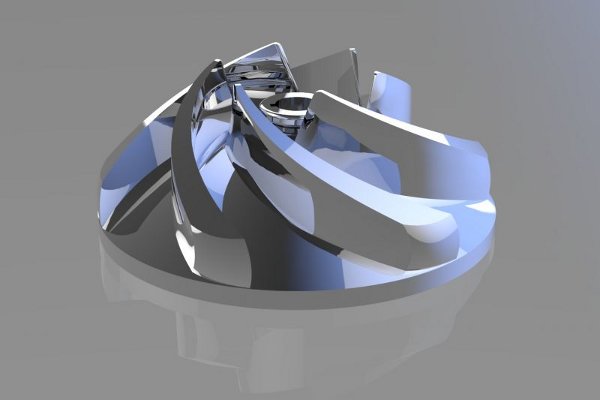

I am pretty confident that 3D Systems is investing in substantially improving Geomagic Design. While, under Alibre’s ownership, it languished for lack of financial resources, that’s not the case now. 3D Systems has the money, technology, and vision to take Geomagic Design to the next level. I don’t know what that level might be, but consider that Geomagic has deep expertise in point clouds, voxels, and NURBS. Might that provide a hint?

MechSoft already provides an upward migration path from Alibre CAM, to its flagship VisualMill product family. The top of the line Premier version includes high-end capabilities, such as 5-axis swarf machining. (This is a method where you use the side profile of the cutter for contouring. Incidentally, my friend Patrick Hanratty invented 5-axis swarf machining. It was quite a feat of mathematics–which probably explains why it’s still considered a high-end capability even today. The article Gentleman Genius tells a bit of his story. It was written, coincidentally, by the same Rachael Dalton-Taggart I mentioned at the top of this article.)

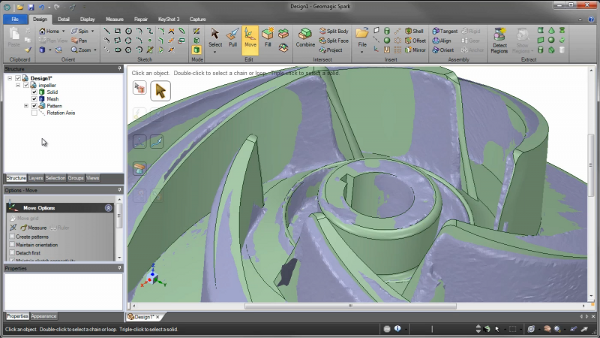

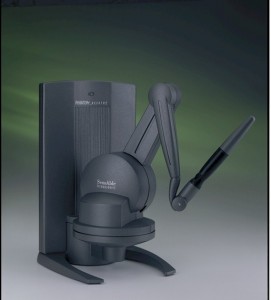

The Phantom/Freeform Plus combination is a “secret weapon” that transforms workflows for products with organic shapes. It does this by supporting voxel (essentially, 3 dimensional pixel) based modeling, with haptics (force feedback.) Using a Phantom with Freeform is like modeling clay with a stylus. (Sensable calls it “digital clay.”) You can actually “feel” the surface you’re pushing against with the Phantom.

The Phantom/Freeform Plus combination is a “secret weapon” that transforms workflows for products with organic shapes. It does this by supporting voxel (essentially, 3 dimensional pixel) based modeling, with haptics (force feedback.) Using a Phantom with Freeform is like modeling clay with a stylus. (Sensable calls it “digital clay.”) You can actually “feel” the surface you’re pushing against with the Phantom.

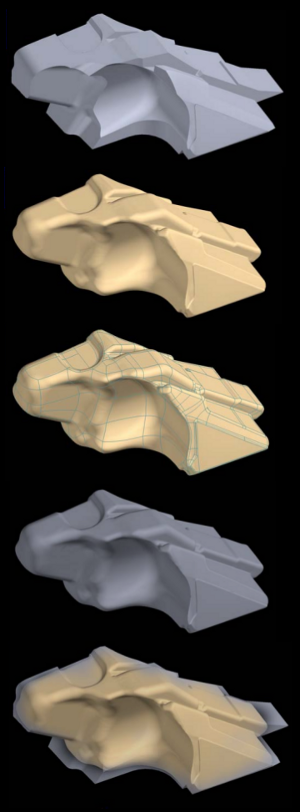

To the left is an example of using Freeform Plus to model a gas tank for a snowmobile. The first image shows a shape, imported in Parasolid format and converted to digital clay (voxels), that defines the volume available for the gas tank. Its shape is derived from surfaces of all the parts surrounding the area, and it’s definitely not pretty.

To the left is an example of using Freeform Plus to model a gas tank for a snowmobile. The first image shows a shape, imported in Parasolid format and converted to digital clay (voxels), that defines the volume available for the gas tank. Its shape is derived from surfaces of all the parts surrounding the area, and it’s definitely not pretty. Freeform and Freeform Plus gain support for 3D Connexion’s SpacePilot Pro and SpaceMouse Pro, for enhanced two-handed 3D manipulation. (If you get one of these, you’ll wonder how you did without it.)

Freeform and Freeform Plus gain support for 3D Connexion’s SpacePilot Pro and SpaceMouse Pro, for enhanced two-handed 3D manipulation. (If you get one of these, you’ll wonder how you did without it.) CAD isn’t the only way to create 3D models. More and more, 3D models start out as 3D scans of real objects. Geomagic has been a leader in software to convert 3D scanned data into useable 3D models. Their software is used widely used for design, reverse engineering and inspection.

CAD isn’t the only way to create 3D models. More and more, 3D models start out as 3D scans of real objects. Geomagic has been a leader in software to convert 3D scanned data into useable 3D models. Their software is used widely used for design, reverse engineering and inspection.