Mr. McGuire: “I want to say one word to you. Just one word.”

Mr. McGuire: “I want to say one word to you. Just one word.”

Benjamin: “Yes, sir.”

Mr. McGuire: “Are you listening?”

Benjamin: “Yes, I am.”

Mr. McGuire: “Plastics.”

– The Graduate, 1967

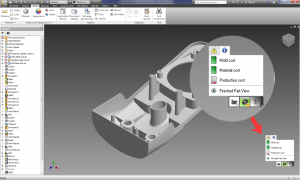

Dassault Systemes SolidWorks Corp this week announced a new product: SolidWork Plastics.

Actually, it’s not strictly new, and it’s not just one product. SolidWorks Plastics was developed and originally sold by Simpoe, a provider of plastics injection molding simulation software. Dassault entered into an agreement whereby SolidWorks will now sell the software under their banner.

There are two versions of SolidWorks Plastics. The Professional version (US$4,995.00) is for people who design plastic injection molded parts. The Premium version (US$14,995.00) is for mold designers.

If you’ve been using SolidWorks for a few years, you might remember that the 2007 version came with MoldflowXpress, a limited function molding simulation tool that included a generic materials database, part-only analysis, single gate location, and a go/no go result, showing whether a part would fill. MoldflowXpress was what you might call a “good enough to be useful, not good enough to take sales from our more expensive products” tool. Still, it was pretty useful, and nicely integrated into SolidWorks. It became unavailable about the same time SolidWorks’ arch-competitor Autodesk purchased Moldflow. (Imagine that!)

After MoldflowXpress went away, Simpoe was one of the companies that stepped up to the plate, to offer a “gold” partner product for plastics simulation running embedded in SolidWorks.

After MoldflowXpress went away, Simpoe was one of the companies that stepped up to the plate, to offer a “gold” partner product for plastics simulation running embedded in SolidWorks.

I’m guessing that users were happy enough with the Simpoe products that Dassault decided to bring them into the fold.

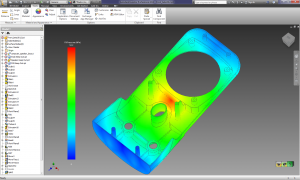

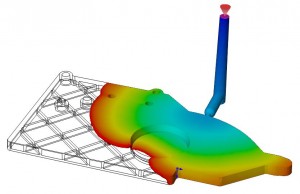

SolidWorks Plastics Professional is quite a bit more capable than MoldflowXpress ever was. It allows parts designers to verify uniform wall thickness (a fundamental best practice of plastics part design), optimize the thickness of features such as reinforcing ribs to avoid sink marks, and predict (and either minimize or eliminate) weld lines. It includes a material database with around 5,000 grades of commercial plastic. It has a very useful set of capabilities for people who design plastic injection molded parts. (And SolidWorks is probably the leading CAD tool for this purpose.) The important thing about SolidWorks Plastics Professional is that it lets parts designers verify manufacturability early in the design process, long before cutting any tool steel. It’s not trivially inexpensive, but compared to the cost of a few trashed molds it’s a bargain.

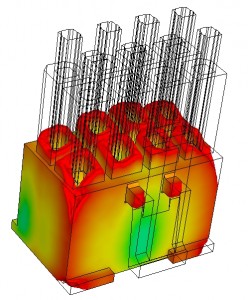

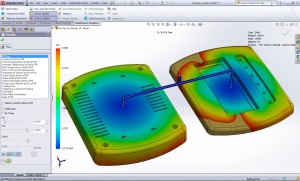

SolidWorks Plastics Premium is for mold designers. It’s a big-time full-function mold analysis tool, supporting analysis of single-cavity, multi-cavity and family mold layouts, runner balance analysis, and providing a wide range of report plot types for identifying and rectifying problems. It comes with automated report generation capabilities, for sharing results with others. A significant benefit of SolidWorks Plastics Premium, when compared to standalone analysis solutions, is that runs embedded inside of SolidWorks, and uses familiar workflows. Its learning curve should be comparatively easy for experienced SolidWorks users. It should go without saying (but probably doesn’t) that learning curve and usability are exceedingly important, even for people who are domain experts.

SolidWorks Plastics Premium is for mold designers. It’s a big-time full-function mold analysis tool, supporting analysis of single-cavity, multi-cavity and family mold layouts, runner balance analysis, and providing a wide range of report plot types for identifying and rectifying problems. It comes with automated report generation capabilities, for sharing results with others. A significant benefit of SolidWorks Plastics Premium, when compared to standalone analysis solutions, is that runs embedded inside of SolidWorks, and uses familiar workflows. Its learning curve should be comparatively easy for experienced SolidWorks users. It should go without saying (but probably doesn’t) that learning curve and usability are exceedingly important, even for people who are domain experts.

While SolidWorks Plastics isn’t technically an entirely new product, now that it’s part of the SolidWorks family, it’ll probably get more attention from resellers, and more awareness among users. All told, a good thing.

DS SolidWorks Corp. www.solidworks.com/sw/products/plastics-injection-molding.htm

For inexperienced designers, Simulation DFM provides quick feedback to help them avoid rookie mistakes. It’s sort of like an “idiot light” on a car’s dash, that warns you when something is wrong. And while old-hands might say they prefer gauges to idiot lights, experience has shown that idiot lights are useful to experts (even F1 drivers and fighter pilots) for catching their attention, and getting them to actually look at the gauges.

For inexperienced designers, Simulation DFM provides quick feedback to help them avoid rookie mistakes. It’s sort of like an “idiot light” on a car’s dash, that warns you when something is wrong. And while old-hands might say they prefer gauges to idiot lights, experience has shown that idiot lights are useful to experts (even F1 drivers and fighter pilots) for catching their attention, and getting them to actually look at the gauges.