Freeform and organic shape modeling can be fun. If you have the right tools. In Organic Shape Modeling for Engineers (in the June issue of Design World magazine), I wrote about several really interesting tools. One that I didn’t write about (because it wasn’t generally available in time for printing deadlines) was Clayoo, from TDM Solutions.

Freeform and organic shape modeling can be fun. If you have the right tools. In Organic Shape Modeling for Engineers (in the June issue of Design World magazine), I wrote about several really interesting tools. One that I didn’t write about (because it wasn’t generally available in time for printing deadlines) was Clayoo, from TDM Solutions.

Clayoo is a Subdivision (SubD) surface modeler that runs inside of Rhino. If you know what SubD surface modeling is, you probably have a good grasp of what Clayoo can do. If you don’t know what SubD surface modeling is, then maybe this will help: It’s like modeling by hand.

Let me explain a bit better: NURBS surfaces can be quite precise. But they’re not easy to model in a push-pull fashion. SubD surfaces are easy to model in a push-pull fashion. But, they’re difficult to make precise (such as when you need an interface between parts. The best of all worlds, then, is to have a SubD modeler that runs inside of a NURBS modeler.

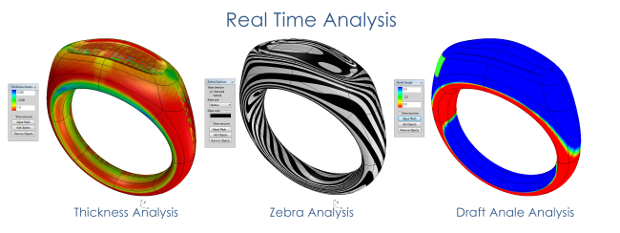

Clayoo is ideal for creating complex freeform shapes, in architecture, jewelry, consumer products, toys, aerospace, marine, furniture, or art. And, while there are any number of SubD surface modeling tools out there that can be used to create freeform shapes, Clayoo has the advantage of being integrated into Rhino, a precise NURBS modeler. With Clayoo, you end up with a Rhino object that’s in traditional NURBS brep form, and that can be used downstream with any other CAD/CAM/CAE product that supports NURBS surfaces and solids. Clayoo surfaces also work with standard Rhino tools, for example, these surface analysis tools:

With Clayoo, you can start with any geometry: surfaces, solids, meshes, or sketches. It also supports a retopology function, which allows you to build clean Clayoo surfaces (and, thereafter, NURBS) on top of poor quality scan data or STL meshes. It’s a pretty neat trick: you end up with a finely-tuned lightweight surface, built the way you want it (rather than the way some translation software wants it.)

Here’s a video, showing the construction of a Clayoo surface on top of an STL model of a car hood:

Clayoo is rather similar to another third-party add-on for Rhino: T-Splines, which was recently acquired by Autodesk. There are some mathematical differences between the approaches used in T-Splines and Clayoo, but, in practical use, the tools can produce similar results. Clayoo is still in beta form (available at www.clayoo.com), and it’s likely to mature, and get new capabilities over time.