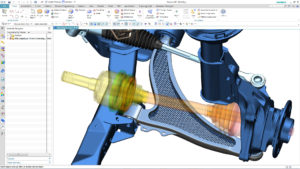

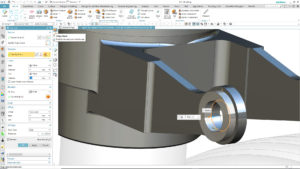

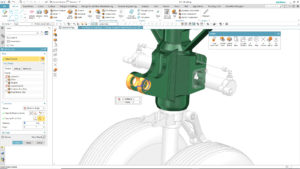

The latest version of NX software includes an expansion of the Digital Innovation Platform that has been enhanced with machine learning (ML) and artificial intelligence (AI) capabilities. These new features can predict next steps and update the user interface to help users more efficiently use software to increase productivity.

The ability to automatically adapt the user interface to meet the needs of different types of users across multiple departments can result in higher adoption rates, leading to a higher-quality computer-aided technology (CAx) system and the creation of a more robust digital twin.

Machine learning (ML) is increasingly being leveraged in the product design process for a competitive advantage. ML can deliver valuable business insights quickly and efficiently, and it has the power to process, analyze, and learn from large volumes of data. AI and ML can also be used to monitor the actions of the user, their success and failures, to dynamically determine how to serve up the right NX commands and or modify the interface and leverage learned UI usage knowledge for CAx environment personalization.

“There’s always been a capability-usability tradeoff with CAD applications. The more expansive it gets, the more difficult it is to use and master,” said Chad Jackson, Chief Analyst at Lifecycle Insights. “The Adaptive UI in NX, however, circumvents that issue. It guides users, new and old, to the right function at the right time. Many will benefit.”

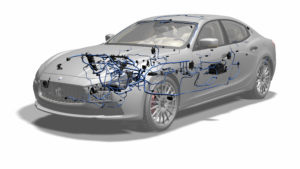

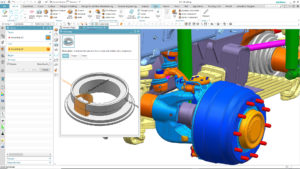

The Siemens Digital Innovation Platform is continually expanding to enable customers to create the most comprehensive digital twin of a product, the production environment and of the performance of the product. Integrating ML and AI into NX software offers benefits of speed, power, efficiency and intelligence through learning, without having to explicitly program these characteristics. Customers can enhance the design process and reduce time to market.

Siemens PLM Software

www.siemens.com/plm