Amid the palpable excitement of its most ardent users, Siemens introduced the latest release of its flagship software, Solid Edge ST7 at this year’s Solid Edge University in Atlanta, Georgia. It’s no wonder the crowd of users was excited; this new release is packed with a staggering 1,300 user-requested enhancements.

The goal of the new release, according to Karsten Newbury, senior VP and general manager of the company’s Mainstream Engineering Software, was to improve the productivity and efficiency of the product design process. “At Siemens we develop software for our users,” says Newbury. “Solid Edge ST7 significantly elevates the user experience; its new enhancements help ensure a much faster, easier learning curve for new users and improved efficiency for experienced ones. This makes our exclusive synchronous technology even more accessible to everybody.”

What’s new?

Sounds good, but time to dig down and take a look at some of the new functionality included in ST7.

Photorealistic rendering. In the April issue of Design World, I wrote a feature on the growing importance of rendering to the product development process. ST7 now offers built-in rendering, courtesy of Luxion’s KeyShot technology, that enable users to quickly and easily create photorealistic images and animations from within the modeling environment, significantly improving the overall image quality and speeding real-time photorealistic rendering of native 3D models by up to five times, based on internal testing.

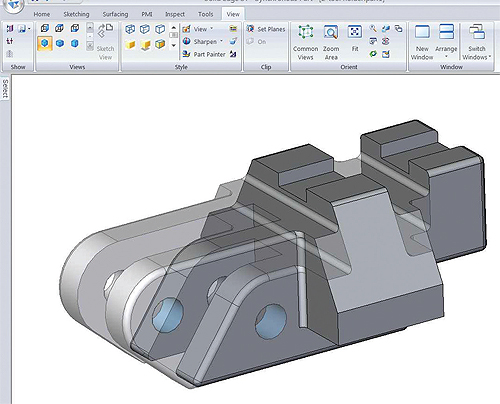

3D Sketching. This new functionality, which is available in the part, assembly and sheet metal environments, improves efficiency with various modeling scenarios, allowing designers to complete their design processes up to two times faster with greater flexibility. 3D Sketch can also be used to model pipes and wires that are bent in more than one plane, and in the assembly environment for the definition of exact paths for piping, wiring and tubing.

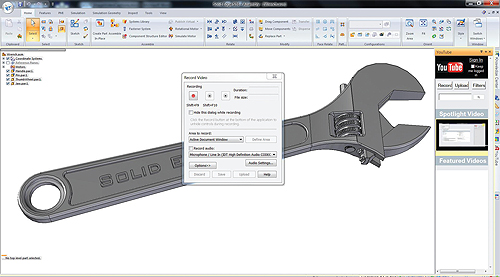

Improved UI. Enhanced user interface features a new start page, focused learning paths, and expanded visual tool tips that all simplify the learning curve for new users and increase efficiency for expert users. Startup page provides easier access to templates, recent documents, instructional videos, and the online community and standard parts.

Visual data management. Design management capabilities, based on Microsoft’s SharePoint software, provide a more visual design management approach with a new workflow site that brings user interactions into one location. This makes it easier to create and work with complex design projects, complete engineering changes faster and improve overall productivity.

Faster assembly design. The Duplicate Component command speeds assembly design in which components are duplicated in many positions and orientations. Multiple copies of a component can be created based on designated “from” and “to” positions and orientations of existing components.

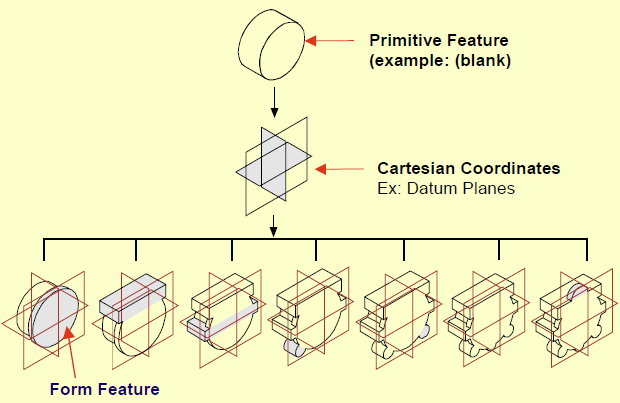

Create a blank from a 3D model. Rapid creation of manufacturing information for components that are manufactured using forming, stamping and deep drawn manufacturing processes is now possible using the “Create Blank” command that enables users to create a flattened blank for any 3D model.

More apps. New Solid Edge apps provide wider capabilities for design, manufacturing and collaboration that speed the entire product development process. New apps include those that provide mobile access to standard and catalog parts; automated output of models for 3D printing; expanded manufacturing capabilities; and cloud-based collaboration. There are now over 500 Solid Edge apps available in the company’s app store.

We’re barely scratched the surface on all the enhancements packed into Solid Edge ST7, so check out this page on the Siemens PLM Software’s web site for more.

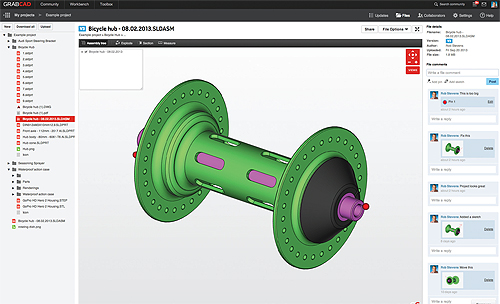

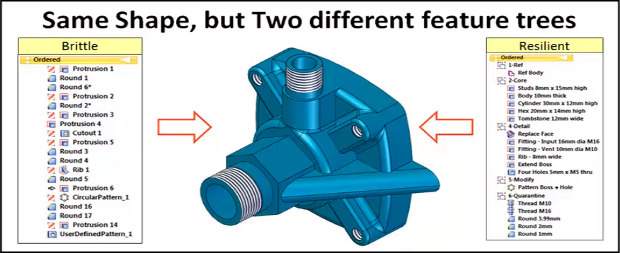

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.

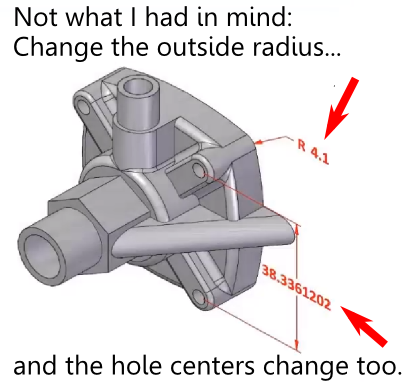

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.