PhD candidate Ahmad Falahatpisheh at the University of California is doing research on artificial heart valve development to improve bioprosthetic heart valves. With the help of Tecplot 360 CFD visualization software to view and analyze his digital particle image velocimetry (DPIV) data, he is helping develop the first bileaflet bioprosthetic mitral valve with dynamic saddle annulus designed to mimic the natural mitral valve.

Tecplot 360 is a numerical simulation and CFD visualization software that combines engineering plotting with advanced data visualization in one product. The software allows you to plot, animate, and analyze data, arrange multiple layouts, and communicate results.

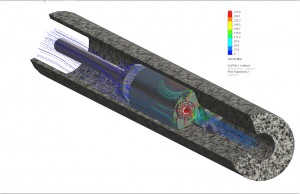

Falahatpisheh has been evaluating bioprosthetic heart valves assembled in an artificial heart flow simulator to examine the transvalvular flow with the help of high-speed DPIV techniques. Using Tecplot 360, he is able to visualize the data related to the flow passing through a valve and identify potential anomalies, clearing the way for the design and development specifically for their dynamic, bileaflet mitral bioprosthetic heart valve.

The use of CFD to study artificial heart valves gives insight to the details of the flow which can be beneficial to the heart valve design process. The challenge is to implement the proper boundary conditions which may lead to the deviation from the physical and realistic solution.

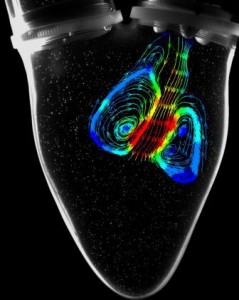

Falahatpisheh imports DPIV data to Tecplot to obtain streamlines which are essential for identifying abnormalities in the flow. This enables him to visualize the streamlines, determine how the flow is structured and moves through time, and gather related information.

Specifically, Falahatpisheh uses Tecplot 360 to look at the vortex patterns and identify valve dysfunctions to help diagnose between a normally functioning heart valve and an abnormal one. The analysis at this stage is critical: it is essential that an asymmetrical vortex pattern is achieved within the flow through the valve. If it shows a symmetric pattern, it means the flow pattern is not optimized to properly transfer the momentum and energy from the heart chamber to the aorta.

Tecplot 360 helps Falahatpisheh identify these flow abnormalities and determine how and where to alter the design to ensure a proper flow pattern. If this portion is inaccurate, all the work and research that takes place after the tests will also be inaccurate. The end goal of his research is to aid in the development and production of a safer, better bioprosthetic heart valve that helps physicians save more lives and improve the quality of life for many others.

Tecplot