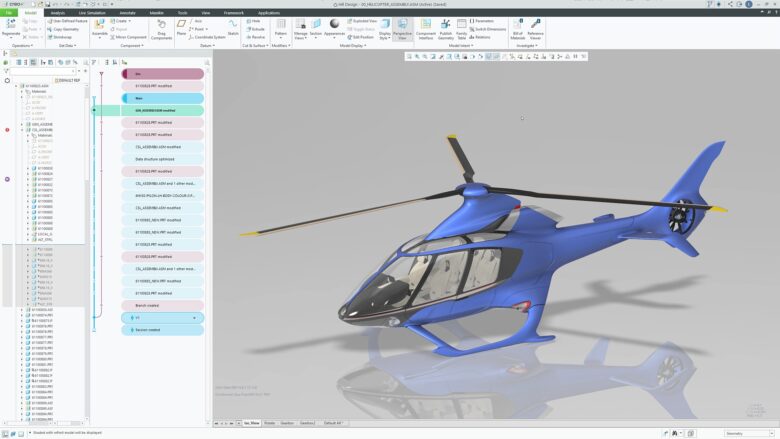

PTC recently launched a new engineering app for the Apple Vision Pro. The Onshape Vision App transforms flat computer screen models into virtual life-size products that team members can hold, pull apart, and inspect as if they were physical components. It works in sync with the Onshape cloud native CAD and PDM system on the iPad, enabling any changes in the product model to be updated in real time with the infinite canvas of Apple Vision Pro.

This provides an opportunity for industries to improve the way dispersed product development teams collaborate and conduct design reviews. The company believes that the earlier a hardware development team gets feedback on a design concept, the more likely they will be able to deliver products that their customers truly need and want. Expanding the pool of stakeholders as soon as you can in the review process also leads to more design iterations and exploration.

Another advantage of completing design reviews with Onshape Vision is that it is extremely welcoming and intuitive for non-CAD users, such as executives, sales and marketing professionals, and customers.

PTC has been committed to advancing spatial computing and associated technologies for the manufacturing industry, primarily through its Vuforia software team and its dedicated Reality Lab. For further information, visit www.ptc.com.