Leaders and experts from industries that design and make places, objects, and experiences report more business resilience amid an increasingly uncertain global landscape, according to Autodesk’s 2023 State of Design & Make report, released earlier this year.

Globally, 79% of respondents said the world feels more uncertain than it did three years ago.

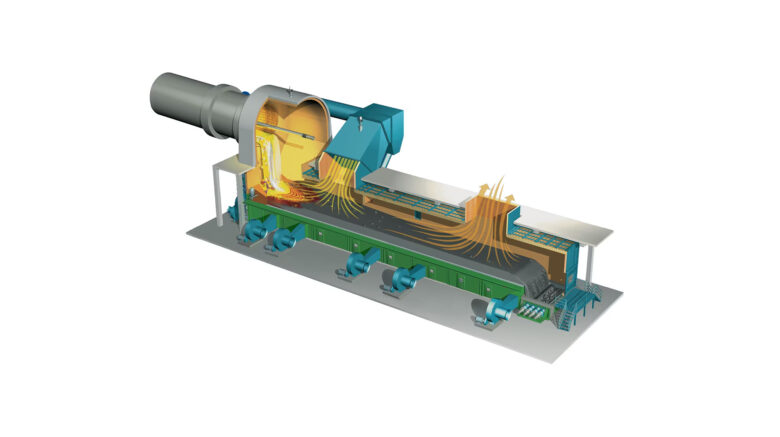

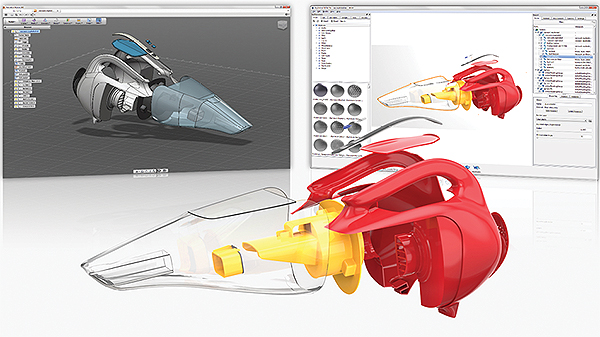

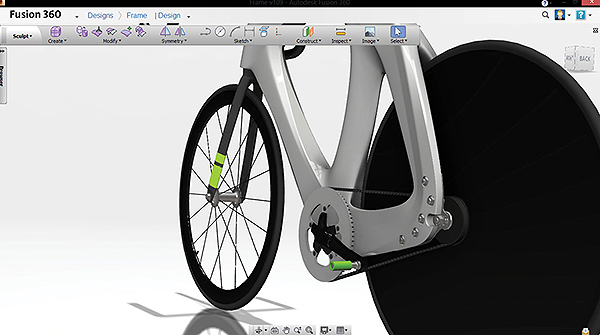

To compile the report, Autodesk conducted a sweeping global study of more than 2,500 business leaders and experts across Design and Make industries, including architecture, engineering, construction, and operations (AECO); product design and manufacturing (D&M); and media and entertainment (M&E).

The top three challenges facing Design and Make companies today are attracting and retaining talent, managing costs, and responding to the volatile global economy and global events. The report also revealed striking differences in resilience and performance for companies classified as digitally mature or further along in using digital tools to transform their businesses.

- More than half of respondents said their companies have hired employees who lack key skills but plan to train them.

- Digitally mature companies are outperforming less digitally mature companies and the performance gap has widened since the start of 2020.

- Nearly 95% of respondents said they expect their industry or organization to make sustainability-focused changes in the coming years.

“Autodesk has uncovered universal challenges and opportunities among industries that design and make the world around us,” said Andrew Anagnost, Autodesk president and CEO. “Across the globe, businesses large and small have made major operational changes over the last three years to stay resilient and relevant. Notably, those businesses which have embraced digitization and data to drive decision making find themselves better positioned to thrive – even against the backdrop of continued global economic uncertainty and turmoil.”

Navigating uncertain times

Globally, 79% of respondents said the world feels more uncertain than it did three years ago. An even greater share of European respondents (86%) felt this way. Factors contributing to the overall sense of unease included war, inflation, Europe’s energy woes, the pandemic, and ongoing refugee crises.

Encouragingly, nearly 6 in 10 respondents considered their company well prepared to handle unforeseen future crises. And leaders of digitally mature companies were 20 percentage points more likely to say they were prepared for future challenges than less digitally mature companies.

“The digital and AI processes are the driving force, allowing us to be personalized and agile,” said Matteo Barale, co-CEO of PIX Moving, an autonomous vehicle start-up.

Talent shortages lead all challenges and impede growth

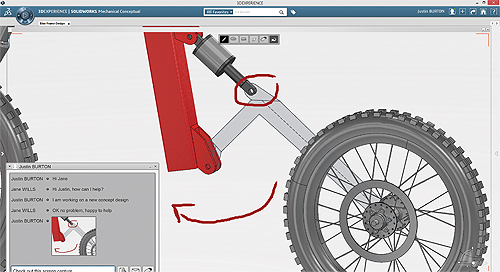

The workforce has evolved more in the past three years than in the previous 25, said nearly 3 in 4 respondents. This is a startling assertion considering the previous quarter century included the rise of the internet, email, smartphones, mobile apps, and mobile computing, but shows how daunting workforce changes caused by the pandemic have been for employers. Attracting and retaining talent is the top challenge for 48% of respondents. Access to skilled employees is posing a barrier to business growth for 64% of respondents. Leaders of digitally mature organizations reported taking more active steps to address the problem.

A total of 93% of respondents said upskilling was important to their companies. Skills of the future included those related to technology, collaboration, and regulatory knowledge.

“In hiring, we’ve been able to attract a lot of people because of our technology infrastructure, which allows us to hire people around the globe,” said Jeremy Smith, CTO for visual effects company Jellyfish Pictures.

Sustainability goals increasingly important

The report showed a consensus emerging on the importance of sustainability. Some respondents said taking sustainability measures will eventually account for a substantial part of their revenue.

Among the findings:

- 80% of respondents said improving sustainability practices is a good long-term business decision

- 82% said customers are influencing their sustainability activities

- Nearly 90% said their industry or organization has made changes to improve sustainability

Decreasing waste, using more recycled materials, and designing with sustainability in mind were among the top changes respondents reported their companies making.

“If we’re digitized, we’re at an advantage,” said Dr. Amy Hochadel, executive director of Global Business for Connected Places Catapult, the United Kingdom’s innovation agency for cities. “I think that’s going to become more and more critical as we deal with climate issues and changing environments.”

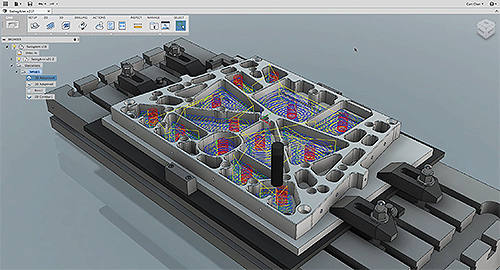

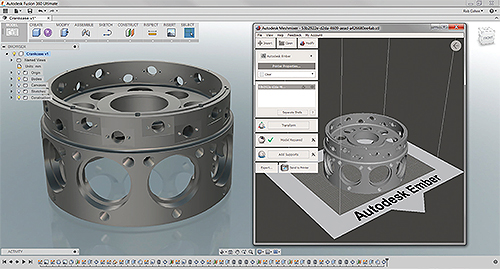

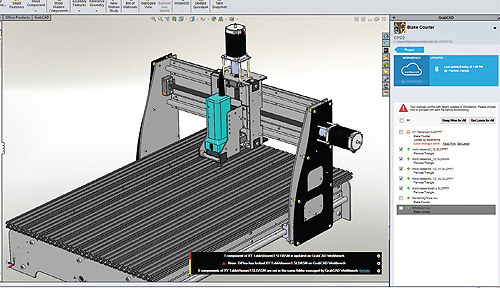

Digitally mature companies primed for growth

Digital transformation is boosting business by reducing costs, increasing innovation, improving performance, and enabling products and services to launch faster. Indeed, 79% of respondents said that the future growth of their company will depend on digital tools.

When Autodesk looked at business metrics including customer satisfaction, profit margin, and revenue from 2019-2021, overall:

- More digitally mature companies outperformed less digitally mature companies

- The performance gap between more and less digitally mature companies appears to grow

More digitally mature companies planned to increase investments over the next three years in:

- Technology to improve project outcomes

- Product or service innovation

- New product or service development

Download the complete findings in the free, 55-page 2023 State of Design & Make report.

Autodesk

autodesk.com