Autodesk introduced the newest version of its desktop 3D CAD product, Autodesk Inventor 2016, which provides a trio of modeling tools: parametric, direct editing and freeform design tools. Inventor 2016 also enables users to associatively connect their Inventor data to non-native CAD formats so their electrical and mechanical data can be integrated into one single design environment.

Work More Efficiently in Multi-CAD Environments

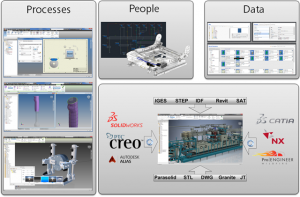

New to Inventor 2016 are features that facilitate working with files and models created in other CAD systems. An associative import of CAD data from CATIA, SolidWorks, NX, Pro-E/Creo, and Alias files allows users to maintain a link to the selected file. The imported geometry in Inventor updates as the model changes.

In addition, a selective import support allows users to only read in the geometry that is vital, speeding the import process. The new Select tab provides you the option to specify which objects to import when importing a CATIA, SolidWorks, Pro-E/Creo, NX, Alias, STEP, IGES, or Rhino file.

Multi-thread support has been enabled, which allows Inventor to more efficiently use available hardware, resulting in improved performance when working on files from other CAD systems. The options for importing CATIA, SolidWorks, Pro-E/Creo, NX, Alias, STEP, IGES, Rhino, SAT, Parasolid Binary files have also been simplified and provide clear choices for import.

With this new version, users can quickly insert an AutoCAD DWG file in an Inventor part file as a DWG underlay using the Import command in the 3D Model tab, Create panel. Users can also now add assembly relationships to underlay geometry.

The Project DWG Geometry command can be used to project DWG geometry, polylines, open or closed loops, and DWG blocks, then the projected sketch elements can be used to create modeling features. 3D Inventor models based on the DWG geometry will update when the 2D geometry changes in AutoCAD.

Mechanical and Electrical Interoperability

The new Electromechanical link between Inventor and AutoCAD Electrical provides a smooth data exchange between 2D and 3D electrical designs. When users create a link between an AutoCAD Electrical and an Inventor assembly, the project files become associative, meaning that design data changes made in one product are updated in the other via Sync.

The Location View command on the new Electromechanical tab on the Assembly ribbon in Inventor displays the devices and wiring contained in both the AutoCAD Electrical Drawings and Inventor Assemblies.

Creating Shapes

Powerful new commands and workflows are now available in Inventor’s Freeform modeling environment. Users can now work with open surfaces or closed shapes; convert existing model faces to freeform geometry for shape refinement; delete faces; unweld edges to split and move a freeform body segment; and use the Freeform Thicken command to create solids, offset surfaces, or shell walls.

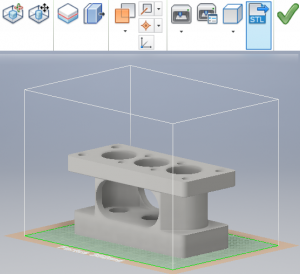

3D Printing

A new environment is added that lets users position and orient their design within the print space of the selected 3D printer. Users can also update the part in the print environment that does not impact the source document. When finished, users can send the results to Print Studio or other printing software to begin printing the part.

Drawing Enhancements

Drawing view creation has been simplified, and uses in-canvas tools. Text formatting is expanded with new options: Bullets and numbering, strike-through text, enhanced formatting (all caps, title case, lower case). Surface texture and feature control frame symbols are updated to the latest standards.

Many new graphical symbols are available, and can be inserted in various types of drawing annotations. Balloon styles can use custom balloon shapes. A new Single Segment Leader option allows users to create drawing annotations with a single leader segment and align drawing annotations vertically, horizontally, or to an edge. Users can create a view sketch on a model with included work features and select those work features with the Project Geometry command.

With a new external Sketch Symbols Library, users can quickly access and share their collection of sketch symbols. The Library is an Inventor drawing file that, by default, is located in a subfolder of the Design Data location of your project. This new feature offers the following new functions:

* A search and filter feature in the Sketch Symbols Library dialog box.

* Preview the sketch in a preview pane within the dialog box before placing the sketch.

* Browser expansion state remains throughout session when placing sketch symbols.

* A Sketch Symbol Library can be created in IDW and DWG formats, allowing insertion of symbols contained within the library file from either format.

* Save your sketch symbols to a customized library.

Visualization

All lighting styles in Inventor Studio are now associated with an Image-Based Lighting (IBL). A lighting style can have zero local lights but must have one IBL. IBL-based styles provides better lighting sources in Inventor Studio with enriched IBL collection.

When users enter the Studio Environment, all legacy local lights are now disabled by default. It is recommended that users utilize IBL for better rendering results. All newly created lighting styles are associated with the default IBL automatically. Change the associated IBL to another IBL as desired.

The enhanced visual effect for shaded visual style makes it more consistent with the realistic visual style. The rendering engine in Inventor Studio was changed to RapidRT with advanced configurations for better quality rendering.

The Studio Render Illustration settings have been moved to the View tab. The new and enhanced Technical Illustration command creates a realistic illustration effect in the graphics window.

Workflow Enhancements

Among the many enhancements, are:

General

* Use Escape (Esc) key to cancel an operation in select processes.

* Multiple productivity enhancements made to dialog boxes.

* Add all window tile styles to the task bar.

* Dock an Inventor browser on any application’s window edge.

* Hide all sketch dimensions now available in the Object Visibility menu.

* Import/Export external rules configuration for iLogic (not available in Inventor LT).

Sheet metal parts

* Multi-body support is added to sheet metal.Support for zero bend radius is added to many commands.

* Material thickness is detected when you convert a part to a sheet metal part.

* Punch tool shows a count of the center selections.

Tube and Pipe setting enhancements

You can now customize file names for fittings and populate part numbers into your parts list within the drawing environment. Previously, you could only change the name of your conduit items, but now you can update fittings as well.

Parts

* Face draft contains powerful new options that let you Fix or Move the parting line.

* Ruled Surface is added to the surfacing commands.

* The Mirror and Pattern commands support multiple solid body selection.

* Previously, nonlinear patterns of a solid body in a multi body part file have not been possible. You can now create nonlinear patterns for solid bodies.

* Drag a sketch above the parent feature in the browser to share it.

* The Measure command now allows you to measure an angle to the midpoint of any segment. This option is achieved by hovering your mouse over the midpoint of a segment until a yellow dot appears.

Sketch

* Identify which workplane or face a sketch was created on.

* The selected Show All or Hide All Constraints display setting remains active as you sketch and throughout your editing session.

* Create tangent dimensions between circular or arc geometry within a 2D sketch.

* The Initial View Scale property of the first drawing review placed on the sheet is added in the Sheet Properties group within the Format Text dialog box.

* The Sketch Dimensions option is added to the Object Visibility list. Select this option to display 2D or 3D sketches and hide all related sketch dimensions.

* Sharing a sketch is made visible by dragging above the feature in browser.

* New snap points added to the context menu: Endpoint, Apparent Intersection, Quadrant, and Mid of 2 points.

* Modify Start Sketch and select a view or sheet before sketching.

Assembly

* New safety factor calculation warning displays in Stress Analysis.

* The Midplane option has been added to the assembly Pattern command. Select the Midplane option to create a pattern distributed on both sides of the original component.

* Replace All feature available for highlighted components within an assembly.

* Select multiple sick constraints within Design Doctor to delete.

Drawings

* Start a drawing from any open model, and automatically apply the current model camera and representations in the base view.

* In-canvas tools in the Base View command simplify creation of a base view and projected views. For example, you can use the ViewCube to orient the model, set the view scale by dragging a view corner, or adjust projected views while creating the base view.

For more detailed information on all the new bells and whistles in Autodesk Inventor 2016, check out its Help Page.

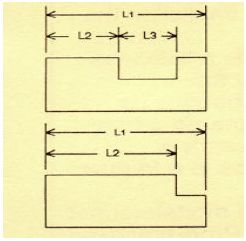

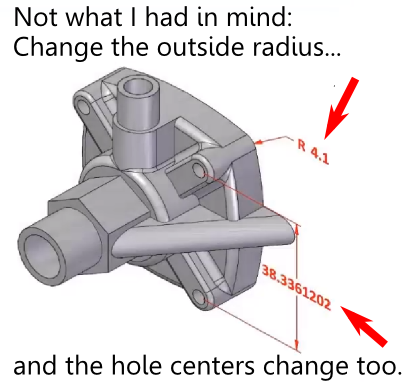

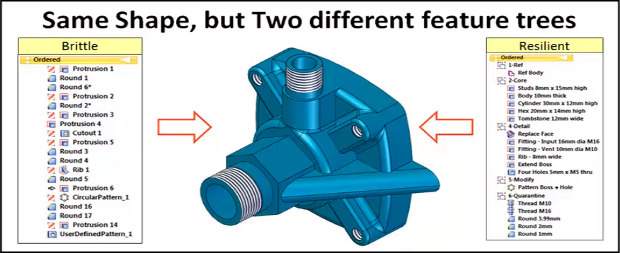

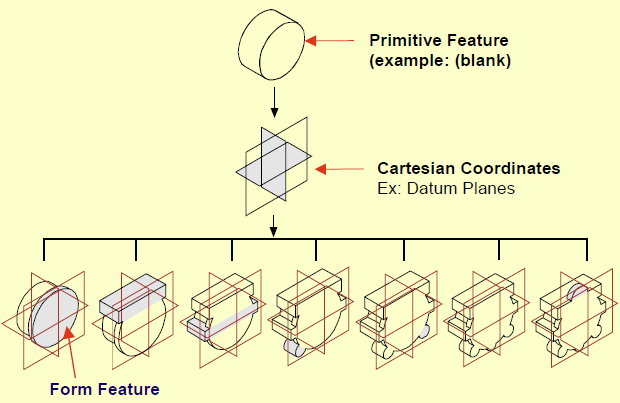

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.

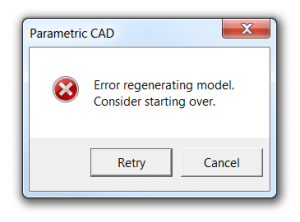

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.