When you think of Harley-Davidson motorcycles, often referred to as “hogs,” its iconic, rumbling sound is often the first thing that comes to mind. The company at one point famously sought to trademark its bikes’ distinctive sound.

It sounds this way because of its unique two-cylinder, v-twin engine design. The engine has a single pin connecting the pistons, originally done to reduce manufacturing costs. To make this unique configuration work the spark plugs were positioned in a 45° arc. So after the first cylinder fires, there is 315° of rotation before the second cylinder fires, and then 405° until the first fires again, and so on, and so on, giving the non-symmetrical distinct potato-potato-potato sound.

Owners love that sound, which sets them apart from the rest of the pack of motorcycle enthusiasts. Imagine their collective horror then when Harley-Davidson announced the debut of its first electric motorcycle prototype, called Project LifeWire, which touts zero emissions.

When the company recently released a teaser video that showed the bike blazing down Route 66, the sounds emitted more closely resembled the sound of a turbine. Response has understandably been mixed among die-hard Harley fans. The company is seeking to attract the novice rider, hoping the lack of a clutch and gears will be less intimidating to newbies.

The LiveWire boasts a 74-horsepower (hp) motor, edging out that of the 60-hp Prius, and according to specs the bike can go 53 miles between charges and takes just 3.5 hours to charge on a 220-Volt outlet. Performance wise, the bike tops out at 92 mph, not bad for a battery-powered bike.

Company deploys high-tech tools to design new bike

Though not everyone has jumped on board the all-electric and hybrid trends in vehicle design, it does show that Harley has one keen eye on the future and will not left in a cloud of dust when the transportation industry–through necessity–eventually moves away from internal combustion engines (ICE).

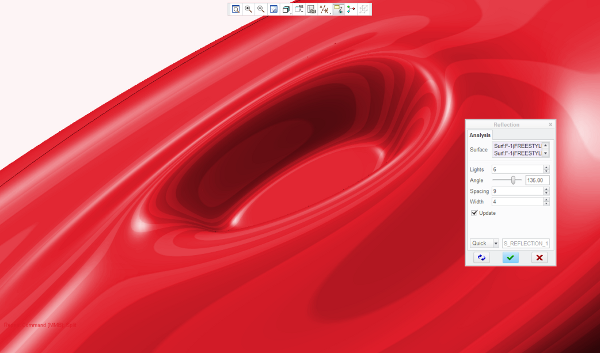

In order to accomplish this rather Herculean task, Harley-Davidson’s design team started from scratch, using the latest in design, prototyping and manufacturing technology. In order to meet demanding production schedules that determine the eventual success of any new product, the company leaned heavily on CAD software for design and FEA software for testing.

The company used PTC’s Pro/ENGINEER (now Creo/Parametric) to design the new bike and finite element analysis (FEA) software to conduct virtual testing on the design before any actual parts were machined or prototyped.

The FEA analysis enabled the designers to conduct design optimization studies to determine the optimum weight versus structural strength and durability. Designers also advanced wire routing software and visualization tools to evaluate the design prior to prototyping.

Harley-Davidson uses 3D printer to create prototype parts

Prior to machining and fabrication, some of the parts for LiveWire were 3D printed in order to validate the tolerances, proportions, and other attributes. Harley-Davidson has several 3D printers that run around the clock to validate designs for both ICE bikes and for other projects like LiveWire.

The 3D printed parts used for validation are full-sized 1:1 scale parts, not shrunk down models. This prototyping process allowed everyone involved in the design and manufacturing process to test, fit, hold, and see parts of the bike in proper proportion.

Once a design was completed, the company’s design team used computer-aided manufacturing (CAM) software to manufacture it. The entire concept-to-prototype process took only four months.

Today, the bike can been seen throughout the country on Harley-Davidson’s LiveWire Experience Tour. The question of whether Harley-Davidson will begin cranking our production models of the concept bike is unknown, but it certainly shows the company has an eye out for the future.

What do you think about an electric Harley? Share your comments below.

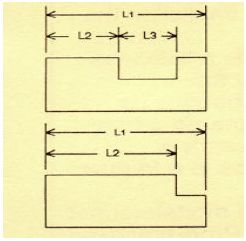

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.

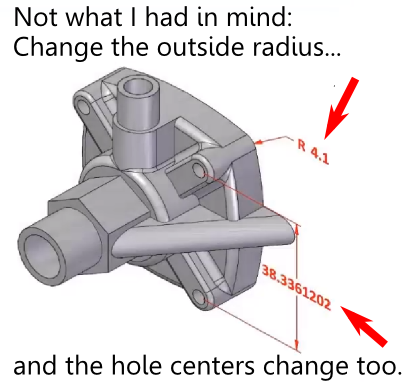

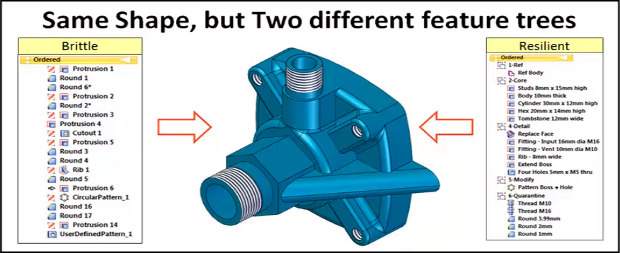

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

Home appliances aren’t what they used to be. Consider, for example, washers and dryers. At this week’s PlanetPTC conference, Fred Bellio, CIO of Whirlpool’s Global Product Organization, and Jeff Burk, Director of Whirlpool’s Constellation Program Management Office, described some of the complexities of his company’s Maytag Maxima line of washers and dryers. Washers and dryers from 50 years ago (when my mother was doing the family’s laundry) were mostly mechanical, with an electric drive motor, a timer, and a few switches, solenoids and relays. The Maxima line are about one-third mechanical, one-third electrical/electronic, and one-third software.

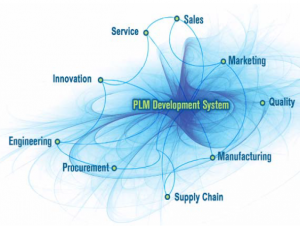

Home appliances aren’t what they used to be. Consider, for example, washers and dryers. At this week’s PlanetPTC conference, Fred Bellio, CIO of Whirlpool’s Global Product Organization, and Jeff Burk, Director of Whirlpool’s Constellation Program Management Office, described some of the complexities of his company’s Maytag Maxima line of washers and dryers. Washers and dryers from 50 years ago (when my mother was doing the family’s laundry) were mostly mechanical, with an electric drive motor, a timer, and a few switches, solenoids and relays. The Maxima line are about one-third mechanical, one-third electrical/electronic, and one-third software. The Constellation program provides Whirlpool with a year-by road-map for implementing PLM technology. This year there are projects related to CAD, core PLM, design quality, cost management, product & portfolio management, service, strategic sourcing, and product quality. It’s not a trivial amount of work. (You can look at Whirpool’s PlanetPTC presentation on Constellation

The Constellation program provides Whirlpool with a year-by road-map for implementing PLM technology. This year there are projects related to CAD, core PLM, design quality, cost management, product & portfolio management, service, strategic sourcing, and product quality. It’s not a trivial amount of work. (You can look at Whirpool’s PlanetPTC presentation on Constellation