Editors and analysts in the tech industry are infamously hard to impress, as most of us have spent years–some of us decades–covering the latest wiz-bang software and gaga gadgetry. Though I still stand behind that statement, I will say there were several moments during my recent visit to Las Vegas for Dassault Systèmes’ 3DEXPERIENCE Forum that left me rather awestruck. Hard to summarize two information-packed days, but I’ll at least share a few of my “wow” moments.

William Teller, the founding editor of Fast Company, was the first speaker. He spoke on the topic of competitiveness today, maintaining that “average is no longer an option anymore” in today’s hyper-competitive markets and that “originality is the new acid test” for competitiveness today.

He also warned the audience to not let their experience and knowledge of their respective products prevent them from being innovative. “The more you know about something, the harder it is to ask those new questions you need to ask in order to innovate,” said Taylor. “You can’t let what you know limit what you can imagine.”

Customers tell the story best

Dassault had a great lineup of customers sharing their stories of how Dassault products are revolutionizing the way they innovate. First up was David Markham from Lockheed Martin who talked about the importance of effective collaboration. Markham said that manufacturers need to create environments for collaborative sharing to solve problems and innovate; what he referred to as “immersive idea dunk tanks.”

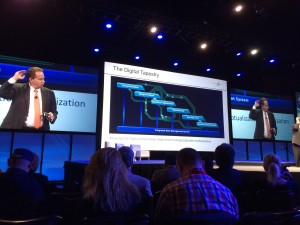

Markham shared Lockheed Martin’s Digital Tapestry that enables them to keep data intact from concept through to manufacturing. The pipeline of data at Lockheed starts at the concept development phase and then moves to design and analysis, simulation and optimization, manufacturing, assembly and test, and operations and sustainment–all integrated in one common data management system.

Tony O’Neil from Anglo America Mining, discussed the how urgent technology advancements are for his industry as well as how important the mining industry is to the economy. “If you can’t grow it, there’s a good chance you’ll have to mine it,” he said. O’Neil lamented that the last great technology breakthroughs in the mining industry are 20 to 30 years old and that the industry needs a 20-year jump in innovation within the next five years.

The challenges faced by the mining industry include declining quality of resources and the fact that they must mine much deeper to reach the materials, which demands better technology. Though it was clear that Anglo America will be relying on the 3DEXPERIENCE platform to help with these much-needed innovation, the specifics of that work was not outlined.

On day two, we heard from Eric De Hoff from Honda who showed off some amazingly realistic visualizations of crash test simulations. He spoke to the importance of simulations looking realistic in order for non-CAE users to fully understand and how visualizations provide a great way to collaborate and communicate with non-experts, AKA executives, which solicited some laughter from the crowd.

The Living Heart Project

Steven Levine heads up the fascinating Living Heart Project, one in which a working computer-based model of a living human heart has been developed and visualized for advancements in heart-related diagnosis and treatment and in the development of medical devices. He discussed how fragmented and disjointed heart research has traditionally been and that the 3DX platform has provided a common platform to bring this project to life.

Levine started his presentation by discussing the irony of how companies would never put people in cars that weren’t fully tested, and yet medical devices, such as heart valves, are often selected based on best guesses of cardiologists and surgeons. He showed a graphic of the Living Heart Project Timeline, adding that they were able to do more in 12 months what it took the collective medical industry ten years to do.

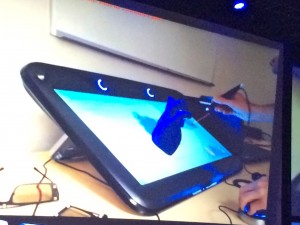

The visualization of the heart model, beating before the audience’s eyes, was beyond realistic looking, literally bordering on grotesque. After the session, I had the opportunity to do a virtual tour of the heart model in the CAVE demo in the 3DEXPERIENCE Playground. Donning 3D glasses and holding a 3D input wand, I was able to explore the heart. Though the demo uses a previous version of the heart model, which is not quite as realistic, it was amazing to be able to probe and see the inside of the virtual heart.

In a poignant and somewhat unexpected moment, Levine shared with the audience that his reasons to advance the Living Heart Project are very personal. His own daughter, now herself in medical school, was born with a heart defect that has required her recently to undergo her third heart surgery to implant a pacemaker.

At the end of Levine’s presentation, Dassault Systemes CEO Bernard Charles, came on stage to announce that Dassault Systèmes has signed a five-year collaborative research agreement with the United States’ Food and Drug Administration (FDA) that will initially target the development of testing paradigms for the insertion, placement and performance of pacemaker leads and other cardiovascular devices used to treat heart disease.

If you are interested in learning more about the Living Heart Project, check out this video.

Puzzles pieces fall in place

I must admit that before attending the 3DEXPERIENCE Forum, I was a sceptic of what Dassault was trying to do with the 3DX platform. It all seemed too abstract and celebral to seem of much benefit to real companies making real products. After seeing some of the work Dassault customers are doing with the 3DEXPERIENCE platform, however, the pieces of the puzzle are definitely falling into place for me.

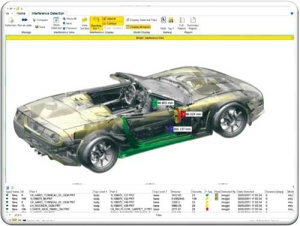

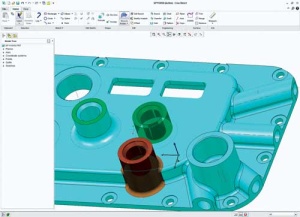

The platform they are delivering to customers is providing them with more insight, which in turn is enabling faster and smarter innovation. The platform certainly is not just for designing products. It’s about having visibility into all facets of your business, your industry, your customers, and your data–of which is delivered through a very intuitive interface.

Overall I found the the 3DX Forum to be quite interesting, especially seeing how Dassault customers are using the 3DX platform to foster their own cultures of innovation.

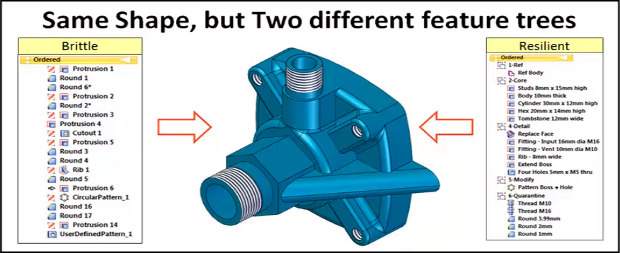

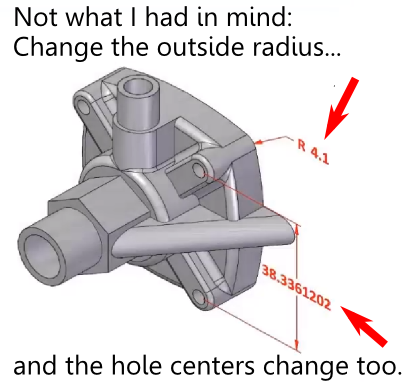

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.