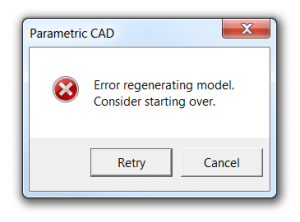

What is the failed promise of parametric CAD? In short, model reuse.

What is the failed promise of parametric CAD? In short, model reuse.

It’s a lot more difficult than it ought to be, for a variety of reasons. Several months back, I wrote a series of articles discussing those reasons, as well as some of the solutions that have come up over the years. What was missing from the series was a final chapter; a detailed description of what could prove to be a viable solution to problems with model reuse: the resilient modeling strategy.

The resilient modeling strategy (RMS) is the brainchild of Richard “Dick” Gebhard. I wrote about Dick last June, in the article A Resilient Modeling Strategy. He’s a low-key guy with deep experience and serious expertise in the practical use of MCAD software. Over his career in CAD, he’s been a reseller for CADKEY, Pro/E, and most recently, Solid Edge.

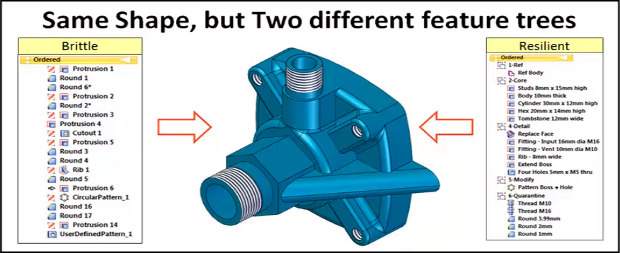

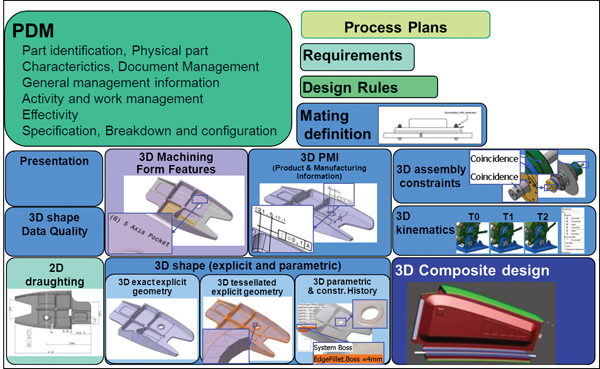

RMS is a best practice for creating CAD models that are stable and easily reusable (even by inexperienced users.) It can be learned and easily used by typical CAD users, it preserves design intent in models, and provides a mechanism by which managers or checkers can quickly validate a model’s quality.

When Dick first started thinking about the concepts that make up the resilient modeling strategy, it was natural that it was in the context of showing the advantages of Synchronous Technology (The Siemens PLM brand name for its version of direct modeling.) In our discussions about RMS over the last year or so, I pointed out that, while I thought that RMS did indeed demonstrate the benefits of hybrid history/direct modeling in Solid Edge, for it to be taken seriously, and not be unfairly dismissed as a marketing initiative for Solid Edge, it needed to work with a wide variety of MCAD tools. I think Dick got where I was coming from, because he’s continued to refine and generalize RMS, with feedback from users of a number of MCAD systems.

In its current incarnation, RMS works particularly well with Solid Edge, as might be expected, but also works very well with Creo, NX, CATIA, and IronCAD (all of which are hybrid history/direct systems.) Further, with a few modifications, it can provide compelling value with SolidWorks, Inventor, and Pro/E (all of which are primarily history-oriented systems.)

It’s significant that RMS is also free to use. While Dick is available to provide presentations, seminars, and training, he has not attempted to patent, or keep as trade secrets, the underlying concepts of RMS. (He does claim a trademark on the term “Resilient Modeling Strategy,” which means that organizations offering commercial training on RMS will need to get Dick’s OK to use the term.)

Dick has posted an introductory presentation on RMS at resilientmodeling.com. While the entire presentation is 20 minutes long, the first 3-1/2 minutes cover the problems that people invariably experience when reusing or editing history-based CAD models. Watching that much will likely convince you to watch the rest.

On Wednesday, November 20, at 10:00 AM PST, Dick will be hosting a webinar on RMS. It’s scheduled to last just 30 minutes, with the emphasis on content, not hype. If you’re a serious CAD user or a CAD manager (or, for that matter, you work for an MCAD developer), it’ll be well worth your time to attend.

TL;DR: Resilient Modeling Strategy is a best practice for creating high quality reusable 3D MCAD models. It works with many CAD systems, it’s easy to learn and use, and it’s free. Big payoff for MCAD users.

Presentation at resilientmodeling.com

Register for Nov 20 webinar on Resilient Modeling

Senior Editor, Evan Yares, will be leaving WTWH Media in the near future to help start up the U.S. operation of Nanosoft, a Russian company. Nanosoft’s products include nanoCAD, a so-called “freemium” 2D CAD product that is free for end users, with a subscription option for premium features and technical support.

Senior Editor, Evan Yares, will be leaving WTWH Media in the near future to help start up the U.S. operation of Nanosoft, a Russian company. Nanosoft’s products include nanoCAD, a so-called “freemium” 2D CAD product that is free for end users, with a subscription option for premium features and technical support.

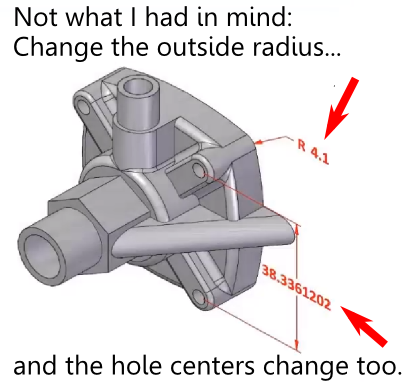

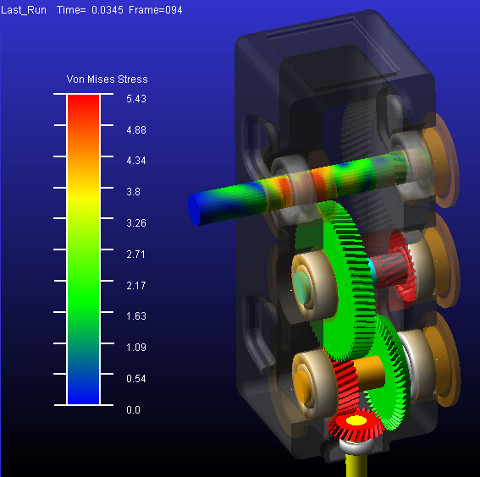

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

The model brittleness problem inherent with parametric feature-based modeling is a really big deal. And it’s something, honestly, that I don’t have a great answer for. I’ve even asked a few power users who I know, and their answers seemed to involve a bit of hand-waving, and a reference to having lots of experience.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

Direct modeling—a syncretic melding of concepts pioneered by CoCreate, Trispectives, Kubotek (and many others)–has shown the most promise to cure the parametric curse.

My friend Rachael Dalton-Taggart, Director of Marketing Communications at

My friend Rachael Dalton-Taggart, Director of Marketing Communications at  Over 10 years ago a company approached CRM Fabrication & Repair with a unique product request. The company specialized in refinishing car wheels, and they wanted a stand that would assist in this process. Of course this was before CRM Fabrication had embraced CNC and CAD/CAM software, so creating a unique product was a little more difficult. They were able to complete the product and ship the order, but it wasn’t pretty, and it wasn’t done efficiently. It was bittersweet when the customer would come back year after year and order more.

Over 10 years ago a company approached CRM Fabrication & Repair with a unique product request. The company specialized in refinishing car wheels, and they wanted a stand that would assist in this process. Of course this was before CRM Fabrication had embraced CNC and CAD/CAM software, so creating a unique product was a little more difficult. They were able to complete the product and ship the order, but it wasn’t pretty, and it wasn’t done efficiently. It was bittersweet when the customer would come back year after year and order more.