Product development has a problem.

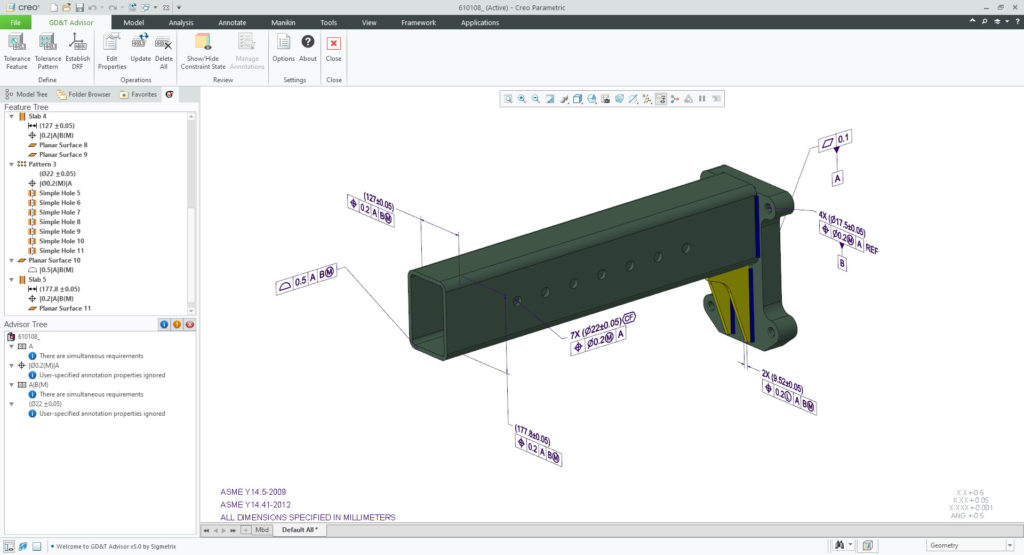

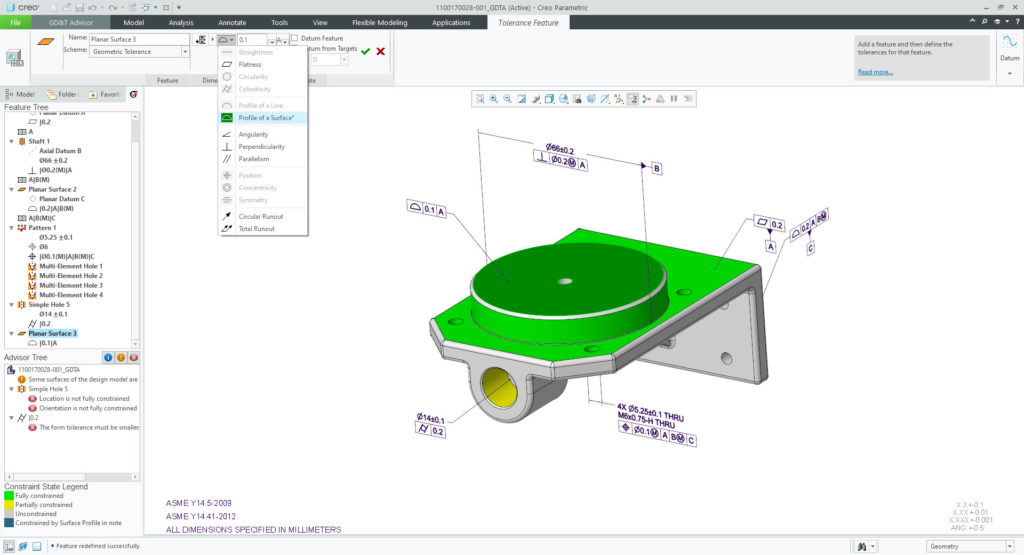

To drive greater efficiencies and higher quality for downstream consumers, organizations have asked product development to adopt model-based definition. This is helping to tie the digital thread from engineering to manufacturing and beyond. But what about within engineering?

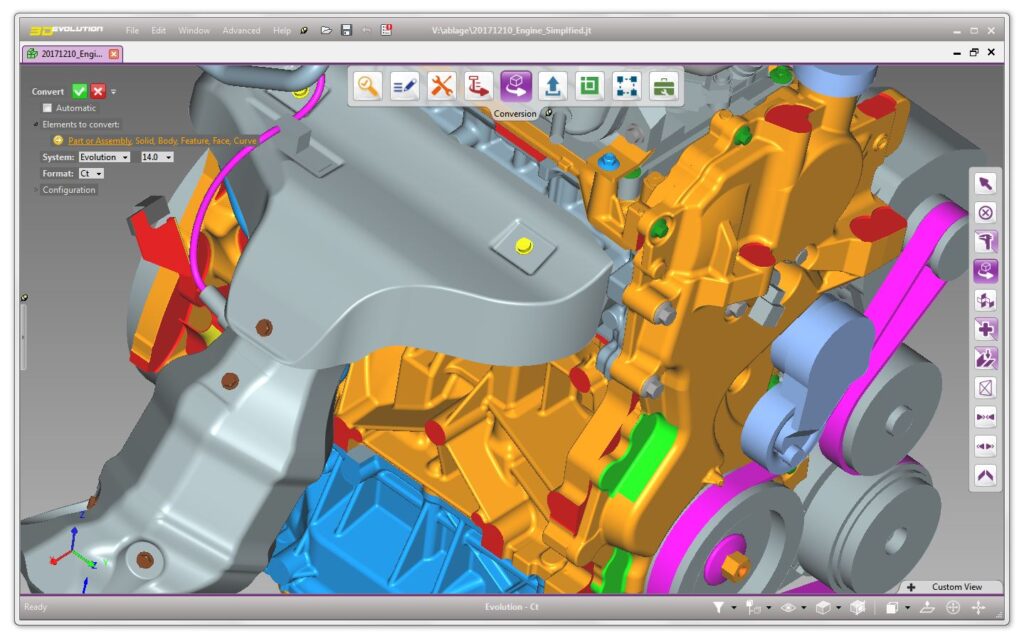

Faced with mounting global competition, increasing product complexity, and a mandate to accelerate delivery cycles, today’s engineers require a robust tool bench to build competitive products. But a best-of-breed portfolio can’t be based on native file formats, which creates all sorts of complications and integration problems when aiming for a universal, annotated 3D model. It also makes it next to impossible to drive comparable efficiencies along the lines of model-based definition (MBD).

The benefits of MBD are becoming increasingly more apparent among leadership, including optimizing design and manufacturing processes. The model-based enterprise (MBE) extends MBD even further into manufacturing, supply chain, marketing, and other disciplines, aiming for across-the-board organizational benefits such as process efficiencies, lower overall costs, and faster time-to-market. Yet there remains a missed opportunity to achieve that full MBE vision.

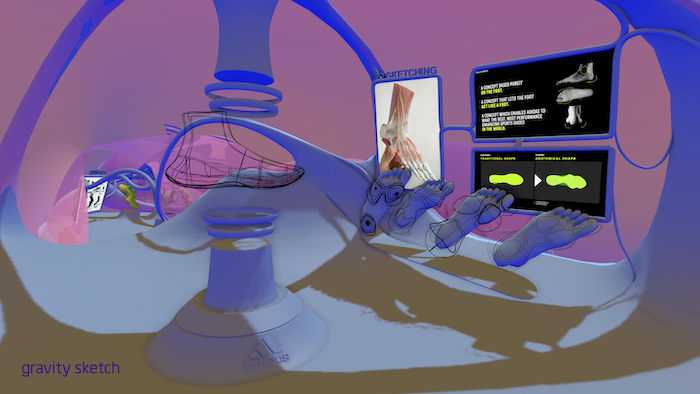

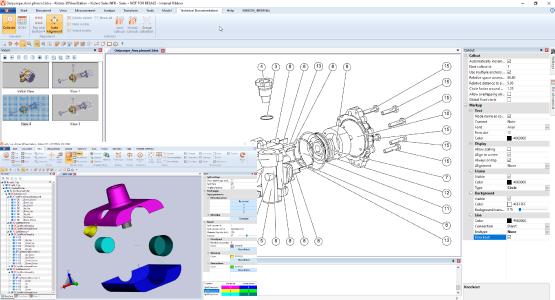

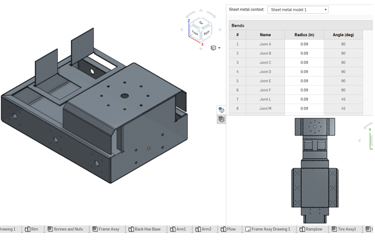

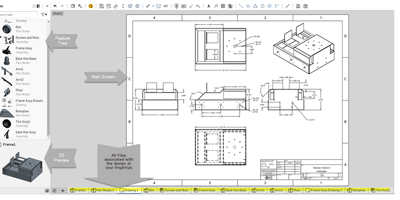

Outside of core CAD modeling and design work, engineers have been tapping best-of-breed, collaborative tools for adjunct functionality in key areas like simulation, generative design, surfacing, tool path creation, and documentation. What’s needed is a Model-Based Product Development approach, which promotes a unified platform and a common CAD model across the core set of tools and functionalities required throughout the engineering lifecycle.

Model-Based Product Development takes shape

Model-Based Product Development is crucial to advancing the vision of the digital thread and MBE. The approach takes shape through a series of interconnected design, optimization, and build processes coalescing around a common, native CAD model instead of derivative artifacts that aren’t tied to the core design. With all contributors working from a unified 3D model, organizations can drive efficiencies throughout the design process and a product’s full lifecycle.

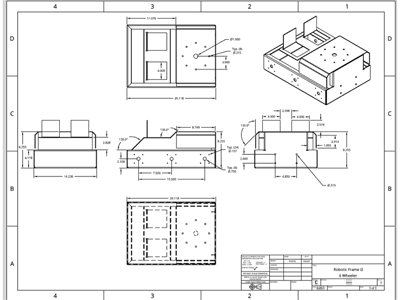

MBD has had a measurable impact on product delivery workflows, streamlining what was once an onerous process of managing 2D drawings and shortening the time spent in design reviews. PTC’s customer research shows a robust MBD approach enables companies to produce documentation up to 40% faster, reduce first article inspection time by 60%, and benefit from a 90% drop in product errors and non-conformances.

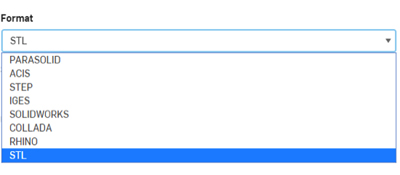

In order to build today’s competitive products, engineers require a robust tool bench. However, a best-of-breed portfolio doesn’t typically share a native file format, which creates all sorts of complications and integration problems. Without a common backbone to work from, product organizations find themselves subsumed by disconnected processes — the tell-tale signs of a landscape dominated by siloed tools and disparate file formats. Engineers wind up channeling too much time and energy to context switching between applications, which takes away from higher-value experimentation and design innovation. With a model that transcends the full design tool stack, translation and integration tasks are accelerated and rework is eliminated — leading to a decrease in design errors and a faster go-to-market.

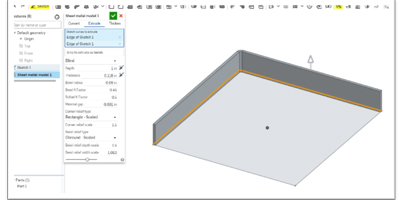

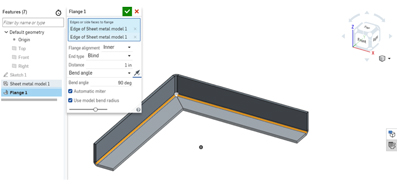

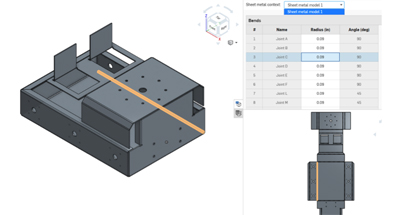

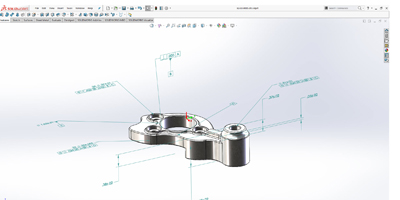

The promise of 3D CAD, and specifically parametric modeling, is that design intent is easily captured using features and constraints, which makes it easier to define how the model should behave when something is changed. Moreover, best-in-class parametric modeling is deeply associative so that when changes occur in one part of a model, the relevant updates are automatically orchestrated to related geometry and downstream artifacts, keeping every point in the design chain in sync.

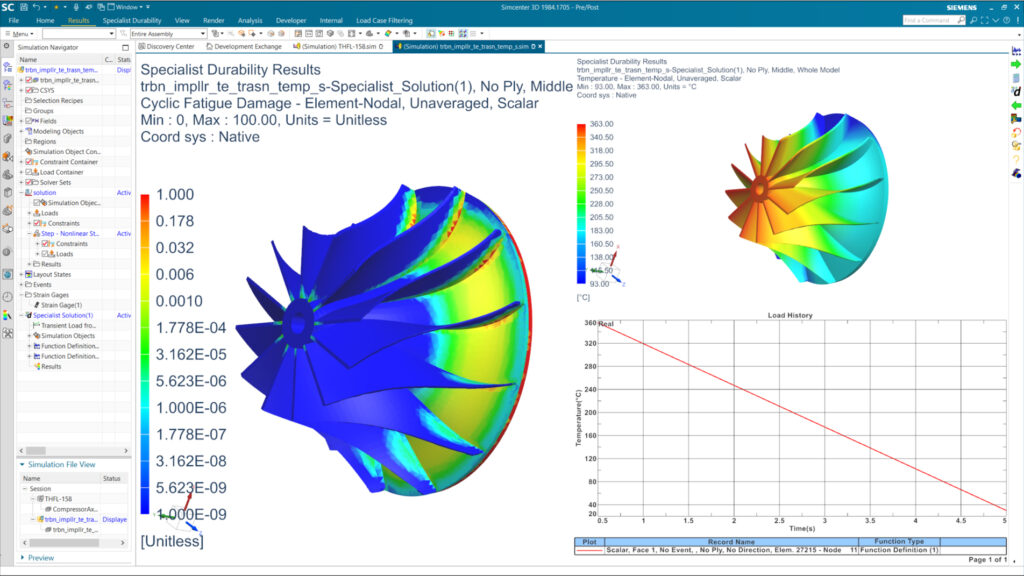

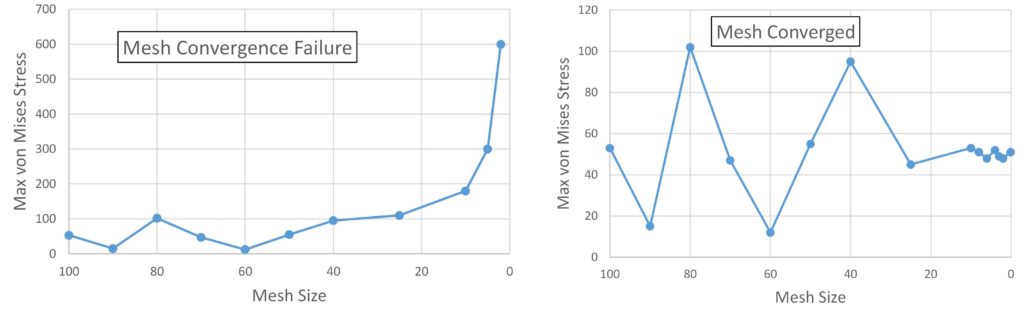

The vision starts to fall apart, however, when point solutions are introduced for enhanced capabilities beyond core CAD modeling. For example, using simulation early in the development cycle to optimize the design space is far superior to simulation being used in the latter stages.

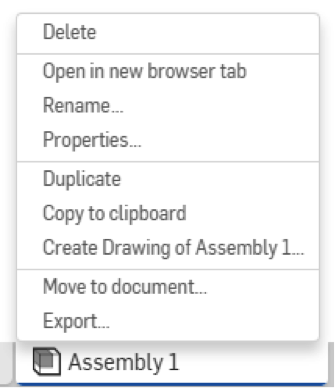

When auxiliary functions are used outside of the main CAD environment, they are not directly associative with the native 3D model. In most cases, if an engineer wants to run a FEA analysis on a part to test strength or to lightweight a particular component using generative design capabilities, they must toggle between point solution tools. This work pattern introduces a cycle of importing, exporting, and translating featureless geometry, which is not only inefficient, but also breaks the tool chain and decreases the inherent benefits of associative parametric design.

Model-Based Product Development at work

You don’t have to look far to find companies across a variety of industries already profiting from their embrace of Model-Based Product Development. HPE COXA, which provides engineering solutions and oversees technology projects in the automotive, motorsport, and defense spaces, was grappling from inefficiencies related to a multi-step, multi-software design process.

The firm was all-in on taking advantage of emerging technologies like generative design, additive manufacturing, and real-time simulation to better product development. Yet to do so required juggling four or five disconnected software tools with different files for each step, which meant the team had to start a process all over again any time they wanted to adjust or test designs. This disjointed approach quickly led to miscues between design and analyst teams, ushered in a host of quality issues, and stalled production times.

HPE COXA was able to reduce total design and production time by 30% and cut the window from concept to delivery in half. HPE COXA consolidated these cutting-edge technologies in a single software, now performing all design steps in a linear, fluid process. The shift helped streamline workflows, simplify communications, and expedite timelines for finished parts.

Making the shift happen

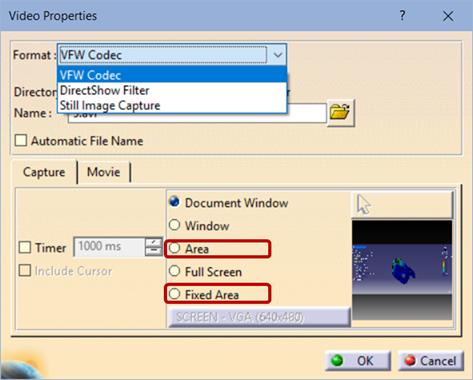

If engineering departments were convinced of the utility of 3D models long ago, why has it taken so long to expand use beyond core CAD functionality? The simple reason is that auxiliary capabilities have been underserved by most CAD tools, steering engineering users to point solutions for more robust functionality. That dynamic has dramatically improved over the last few years as leading CAD vendors like PTC acquired or built advanced functionalities like real-time simulation and generative design and integrated them into the native CAD environment.

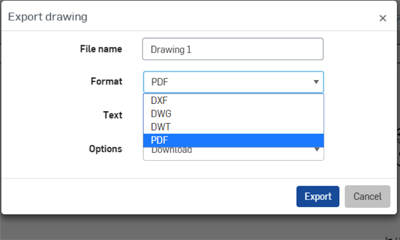

Organizations looking to make the leap to Model-Based Product Development should look for an open system built around the native CAD file format that offers the breadth and depth of capabilities to support the entirety of the design process whether that’s simulation or some element of conceptual design. It’s also important for the system to work in concert with a PLM platform — again, supporting the same native CAD file format — to streamline and simplify key processes like release and change management.

As with any shift in process, there’s likely to be pushback from engineers, who are notoriously resistant to change. Enlisting executive sponsors, many of whom are already champions of MBD and MBE, can help motivate the engineering ranks to get on board and embrace new tools and work patterns.

As companies advance digital strategies, Model-Based Product Development will be crucial to achieving MBE’s full value. It’s well past time for engineers to unleash the power of a model-based approach throughout the development process and reap the rewards of a transformative design chain.

PTC

ptc.com