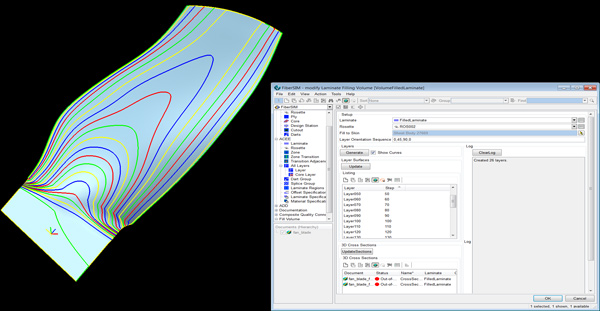

You may know that Siemens PLM recently acquired Vistagy, whose Fibersim software has been used to design 80% of the composites currently flying in today’s aircraft.

Vistagy has been a long-term third-party partner not just to Siemens PLM, but also to Dassault Systemes. Though DS has its own composite design solution, many of its most important customers use Fibersim. To say Vistagy has been an important partner for DS would be an understatement.

My interest in Vistagy is as a microcosm of the relationship between Siemens PLM and Dassault Systemes. Let’s face it: These two companies are serious competitors. Has Siemens acquisition of Vistagy upset a tenuous détente (if it can even be called that) between these two giants of PLM?

This week at Siemens PLM Connection, I got a chance to speak with Steve Luby, the current Sr. VP of Siemens’ Specialized Engineering Software business segment, and former CEO of Vistagy. He told me that he’d always been careful in maintaining Vistagy’s relationship with DS. Since Vistagy had been a long-term partner to both DS and Siemens PLM, he got used to treading carefully. Since the Siemens acquisition, Luby explained, DS has not done anything precipitous (such as tossing Vistagy/Siemens out of their partner program.)

But that’s not surprising. Doing that would be the equivalent of mutually assured destruction. It’d be tough to explain to the biggest aerospace firms in the world that, oops, they can’t use Vistagy’s products anymore.

My guess, though, is that DS is focusing big energy on improving their composite solution (which I understand is mighty competent already), with the eye to displacing as many seats of Fibersim as they can. Yet, even in the best of all worlds, that’s going to be hard to do. I can’t imagine Boeing, for example, dropping Fibersim from the toolset used on the 787 Dreamliner—a plane that’s 50% composites by weight.

I don’t anticipate that DS is going to open their doors, and let Siemens/Vistagy have completely unfettered access to their APIs (and customers!) The current Vistagy products, including applications for composites, airframe fasteners, and automotive/aerospace seating, are probably grandfathered in. But future Specialized Engineering (i.e., Vistagy) products?

It’s a big wild-card. The new Codex of PLM Openness that both DS and Siemens recently signed would suggest that the companies are going to play nicer together than they have in the past. Yet, my reading of the Codex is that it gives an awful lot of wiggle room.

The Siemens Vistagy acquisition presents a nice public context for DS to show that they’re committed to openness. To playing (competing) nice. If my reading between the lines is right, the situation is “so far, so good.” If you’re a Vistagy customer, and you hear anything different (good or bad), I’d sure like to hear about it.