The latest version of Siemens’ NX software has been released, touting among many things increased design flexibility and up to 3X higher productivity for users. New tools, such as the 2D concept development solution, make it easier and faster to create designs, while enhancements to NX Realize Shape software, a fully integrated sub-division modelling environment, provide designers with more flexibility to produce unique shapes.

A new optional touch-enabled interface provides expanded access to the full design capabilities of NX. And tighter integration to product lifecycle management (PLM) software–through Siemens’ Active Workspace environment–reduces the amount of time spent searching for product information. NX 10 also includes multiple enhancements throughout the integrated computer-aided design, manufacturing and engineering (CAD/CAM/CAE) solution.

These include:

2D concept development. Increasing product complexity makes 3D modeling the preferred method of product design throughout the world. However, in some industries including machinery and complex electronics, it is easier and faster to create initial design layouts in 2D. The new 2D concept development solution enables designers to explore concepts in 2D, making it up to three times faster to create new designs. Once the design is finalized it can easily be migrated to 3D to complete the model.

Enhancements to the NX Realize Shape. Enhanced solution give designers even more control over geometry modelling to produce products with highly stylized shapes or complex surfaces. NX Realize Shape is based on sub-division modelling, a mathematical approach to creating 3D geometry with smooth flowing shapes, pioneered by the entertainment industry. The tool is seamlessly integrated with NX which helps shorten product development time by eliminating the multiple steps associated with using separate tools for freeform design and engineering development.

Optional touch-enabled interface. This interface adds the flexibility of accessing NX on tablets running Microsoft’s Windows operating systems, making it easier to use NX when and where needed to enhance collaboration and productivity. Combining improved access to NX with tighter PLM integration through Active Workspace, the innovative interface to Siemens’ Teamcenter software, enables users to quickly find relevant information, even from multiple external data sources. Active Workspace can be accessed via the web on any device from any location.

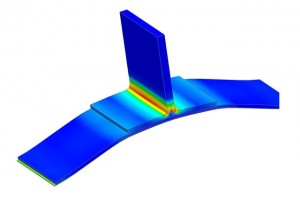

Enhanced multiphysics capabilities. Significantly enhances simulation integration by connecting two or more solvers to streamline the process of performing complex simulations. The multiphysics environment delivers a consistent look and feel for performing multiphysics simulations so engineers can easily build coupled solutions on the same mesh using common element types, properties, boundary conditions, and solver controls and options.

Industry-specific capabilities in NX CAM. Helps engineers program faster and machine higher quality parts. New dynamically-adjusted roughing strategies automatically adapt to part geometry to enable better mold and die machining. New automated inspection programming capabilities in NX CMM (coordinate-measuring machines) enable the use of PMI (Product Manufacturing Information) to create inspection scanning paths. This helps significantly speed up the inspection process compared to the currently available touch point method.

Production line design. NX 10 also includes new production line design capabilities for automotive assembly manufacturing. The new line designer application enables engineers to design and visualize layouts of production lines in NX, and use Teamcenter and Siemens’ Tecnomatix software to manage the designs, and validate and optimize manufacturing processes.

NX 10 will be available in December. For more detailed information on all the new functionality in NX 10, please visit here.

Leave a Reply

You must be logged in to post a comment.