COMSOL, a provider of multiphysics modeling, simulation, and application design software, announced the expansion of its office in Shanghai, China. A larger facility enables continued expansion and recruitment of technical and sales staff to keep pace with the growing COMSOL® software user base in China and increasing demand for COMSOL Multiphysics® and COMSOL Server™ products. Services in Shanghai include sales, technical support, training sessions, and on-site workshops and customer visits.

“We are very excited to expand our office in Shanghai,” said Lei Chen, Managing Director of COMSOL Co., Ltd. in Shanghai. “Training sessions in areas such as multiphysics, mechanical, electrical, chemical and fluid flow will be offered in our new in-house educational facility to teach customers new to COMSOL Multiphysics and COMSOL Server products. More office space also allows us to expand our technical support team to better assist our customers in China. Additionally, we are expanding our localization team to provide more technical material (documentation, model examples) in Chinese.”

The Shanghai office expansion coincides with the latest release of COMSOL Multiphysics® with a more powerful Application Builder and COMSOL Server™. The new version provides simulation experts with a cutting edge user experience in simulation app design and app sharing by integrating highly productive model building, app design, and deployment tools that allow their simulation applications to be shared with users everywhere. With the Application Builder, companies can communicate across multiple departments, knowing that the simulation specialist is able to maintain control, enforce quality standards, and ensure that the results can be trusted.

“Expansion of COMSOL Shanghai office allows us to increase our high quality technical team to support the fast-growing COMSOL community in China,” said Gang (Martin) Wang, Technical Director of COMSOL Co., Ltd. in Shanghai. “Our applications team is dedicated to helping our users learn how to use COMSOL Multiphysics and COMSOL Server and build a wide array of easy-to-use yet powerful simulation apps.”

Comsol

www.comsol.com

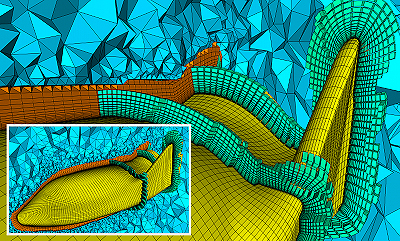

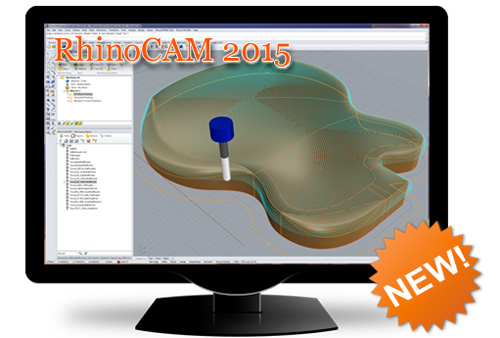

MecSoft Corporation has announced the availability of RhinoCAM 2015, a major version release for MecSoft’s integrated CAM solution for Rhino. RhinoCAM 2015 includes four CAM modules MILL, TURN, NEST, and ART, each of which run completely integrated inside the Rhino 5 CAD program.

MecSoft Corporation has announced the availability of RhinoCAM 2015, a major version release for MecSoft’s integrated CAM solution for Rhino. RhinoCAM 2015 includes four CAM modules MILL, TURN, NEST, and ART, each of which run completely integrated inside the Rhino 5 CAD program.

SolariaPCB

SolariaPCB