Maplesoft today announced that it has now become a Dassault Systèmes SolidWorks Certified Solutions Partner. This is a progression of the relationship between the two companies that has already enabled engineers to connect Maple and MapleSim, with SOLIDWORKS, a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) program.

Maplesoft today announced that it has now become a Dassault Systèmes SolidWorks Certified Solutions Partner. This is a progression of the relationship between the two companies that has already enabled engineers to connect Maple and MapleSim, with SOLIDWORKS, a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) program.

Integration of SOLIDWORKS with Maple, the complete, rapid solution development environment, gives users a seamless way to import CAD model parameters into Maple. This gives them access to Maple’s advanced analysis tools for rigorous mathematical analysis and optimization. Users can then export updated model parameters from Maple to SOLIDWORKS.

By importing multibody CAD models from SOLIDWORKS into Maplesoft’s modeling and simulation platform, MapleSim, users can automatically capture the kinematic and kinetic properties of the model components. They can also evaluate how mechanical CAD models will behave as part of a larger, multidomain system, and apply MapleSim’s advanced analysis tools to improve and optimize designs.

Maplesoft

Dassault Systèmes, the 3DEXPERIENCE Company, has announced that Paul DiLaura has been named Managing Director of North America. DiLaura will be responsible for managing and growing all aspects of Dassault Systèmes’ North American business operations and accelerating the adoption of the 3DEXPERIENCE platform.

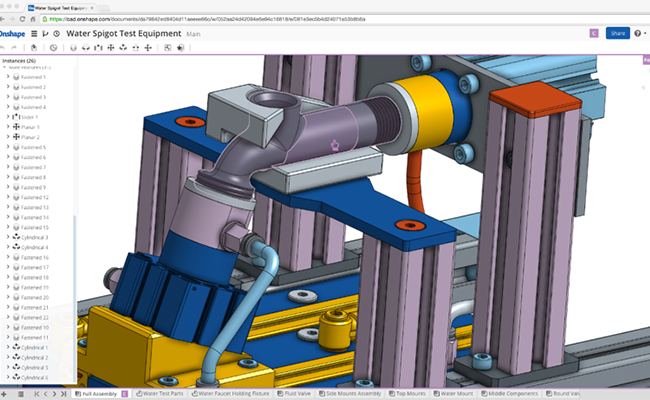

Dassault Systèmes, the 3DEXPERIENCE Company, has announced that Paul DiLaura has been named Managing Director of North America. DiLaura will be responsible for managing and growing all aspects of Dassault Systèmes’ North American business operations and accelerating the adoption of the 3DEXPERIENCE platform. Nason, a South Carolina-based manufacturer of hydraulic and pneumatic cylinders, switches and transducers, employs new thinking which is derived from a total market-driven approach. Nason adapts to customer requirements rather than the customer adapting to available products. This new way of thinking has been the catalyst for their interactive product configurator and 3D CAD model downloads powered by CADENAS PARTsolutions. The new configurator will make it much easier for Nason customers to visualize the wide variety of configurations available for every product, while making it quick and painless to specify and integrate those products into their designs.

Nason, a South Carolina-based manufacturer of hydraulic and pneumatic cylinders, switches and transducers, employs new thinking which is derived from a total market-driven approach. Nason adapts to customer requirements rather than the customer adapting to available products. This new way of thinking has been the catalyst for their interactive product configurator and 3D CAD model downloads powered by CADENAS PARTsolutions. The new configurator will make it much easier for Nason customers to visualize the wide variety of configurations available for every product, while making it quick and painless to specify and integrate those products into their designs.  Maplesoft has announced a major new release of its flagship product, Maple, the mathematical software that makes it extremely easy to analyze, explore, visualize, and solve math problems. With Maple 2016, Maplesoft offers important new abilities to educators, researchers, scientists, and engineers that allow them to solve more problems, more easily, than ever before.

Maplesoft has announced a major new release of its flagship product, Maple, the mathematical software that makes it extremely easy to analyze, explore, visualize, and solve math problems. With Maple 2016, Maplesoft offers important new abilities to educators, researchers, scientists, and engineers that allow them to solve more problems, more easily, than ever before. ESPRIT CAD/CAM SOFTWARE enters a new era with the launch of its new brand identity and corporate website, espritcam.com. The website showcases an elegant new 3D-style logo that updates yet honors the company’s original one.

ESPRIT CAD/CAM SOFTWARE enters a new era with the launch of its new brand identity and corporate website, espritcam.com. The website showcases an elegant new 3D-style logo that updates yet honors the company’s original one.

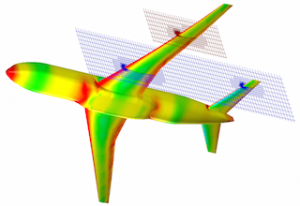

MSC Software Corporation has announced the new release of SimManager 2015. SimManager 2015 brings process enhancements and improved ease of use to MSC Software’s Simulation Process and Data Management solution with an intuitive user interface and easy deployability. SimManager 2015 is the most comprehensive version released by MSC Software, delivering revolutionary process automation and enhanced data collaboration, all with configuration, not customization.

MSC Software Corporation has announced the new release of SimManager 2015. SimManager 2015 brings process enhancements and improved ease of use to MSC Software’s Simulation Process and Data Management solution with an intuitive user interface and easy deployability. SimManager 2015 is the most comprehensive version released by MSC Software, delivering revolutionary process automation and enhanced data collaboration, all with configuration, not customization. Mentor Graphics Corporation

Mentor Graphics Corporation