No two runners are the same. This is especially true for athletes competing at the most elite levels. Their foot-strike patterns, degrees of pronation (the amount a runner’s foot rolls inward with each step), and braking and propulsion forces are all unique. However, the extent to which most running shoe models vary is rather limited in comparison.

As a result, there are some who believe that personalizing a runner’s shoes, specifically the spike plate that provides traction on the underside of the shoe, can help these athletes become faster on the track.

A proponent of this trend is New Balance Athletic Shoe, Inc., best known simply as New Balance.

The company embraces innovation across all platforms of the business and continuously explore advanced methods for product design and production so it’s no surprise that New Balance has turned to design-driven manufacturing for 3D printing custom spike plates, based on an individual runner’s biomechanics and personal inputs, for their elite athletes.

Using a proprietary process to collect race simulation data from Team New Balance runners, the Sports Research Lab then applies advanced algorithms to translate this information into an optimized design that can be additively manufactured on an EOSINT P 395 system—plastic laser-sintering technology from EOS that allows designers to produce, or “grow,” complex geometries that can’t be created using traditional manufacturing techniques.

“There are so many great things that came out of this process, compared to the methods we used in the past to develop and manufacture products,” says Sean Murphy, senior manager of innovation and engineering at New Balance. “This is a totally unique situation where we come away with the runner’s data, generate multiple plates we feel will meet their needs, and actually provide several pairs of track spikes for them to try simultaneously. It’s great to be able to have them identify and respond to each different variation that we produce.”

Customized Design with the Runner in Mind

Long before the spike plates are additively manufactured, or even designed, New Balance’s Sports Research Lab collects each runner’s biomechanical data using a force plate, in-shoe sensors, and a motion-capture system worn by the runner. The motion-capture system helps determine the relationship of the foot to the force plate, creating a three-dimensional vector recreation of the foot strike (i.e. the impact of each stride).

The in-shoe sensors show discrete pressure information over the course of the runner’s foot strike and how the runner’s foot interacts with the shoe. When a particular part of the foot exhibits high pressure values, it generally indicates that the associated 3D vector is important to that area of the shoe at that specific moment in time.

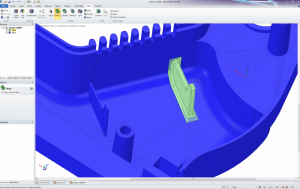

“We establish a relationship between these high pressures and the corresponding forces to help us create a map of forces relevant to each area of the foot,” says Murphy. “A simple example is in the toe area. Generally, when you see high pressure there, it corresponds to a force that is pushing toward the heel to create a propulsive force forward. We use parametric modeling software to process this data and distribute the position of the spike plate traction elements, calculate the orientation and adjust the size of the elements, and incorporate specific runner preferences into the design.”

The designer is then responsible for performing the CAD “cleanup” necessary to create the final product, including touching up model surfaces and making adjustments to accommodate the full-size range of the spike plate. Once the final geometry has been verified, the CAD files are converted to .stl files and uploaded to the EOSINT P 395 system for layer-by-layer manufacturing.

of the plate toward the heel).

Side-lining Traditional Techniques

Track-shoe spike plates have three general characteristics that can vary depending on the length of the race the athlete is competing in and their preferences: The fit, stiffness, and design of the plate all impact the comfort and performance of the runner. Typically, each spike-plate style requires several injection molds for various sizes, all costing thousands of dollars. These molds will run thousands of plates before being retired or replaced, often annually, by a new mold indicating a new model. Currently, the laser-sintered batch sizes produce around four unique plate pairs and take five to six hours to manufacture.

“By laser sintering our customized spike plates we can manufacture on demand, fluidly adjust our process to accommodate different sizes and widths, and update designs without the continuing capital investment required by injection molding,” says Katherine Petrecca, business manager of New Balance Studio Innovation. “The incorporation of the laser-sintered spike plate also allows us to realize a five-percent weight reduction compared to traditionally manufactured versions.” For a competitive runner, the smallest change in weight can make a significant difference.

The development and production of the custom 3D printed spike plates isn’t the only thing that separates these shoes from their off-the-shelf counterparts. While traditional track spikes are commonly made of thermoplastic polyurethane (TPU) and polyether block amide (PEBA), New Balance worked with high-performance materials manufacturer Advanced Laser Materials, part of the EOS family, to develop a proprietary nylon blend.

“We decided to collaborate with ALM on this project because they had experience developing the type of material we were looking for,” says Murphy. “We had worked with them on a previous prototyping project and the variety of materials, as well as knowledge, that they offered made them the perfect partner.”

The spike plates are “grown” in the EOS system from the custom-blend nylon powder, coupled with tailored laser conditions, and yield maximum engineering properties such as tensile and flex moduli, while minimizing build time. Post production includes standard processing techniques such as bead blasting (the process of removing surface deposits by applying fine beads at a high pressure without damaging the surface), after which the plates are processed through a proprietary system for aesthetic finishing and coloration.

The Proof is in the Personal Records: One Runner’s Story

With all the time and energy put into the research and development process, there is still one important question: Does it make a difference in the performance of the runners who wear such customized spike plates? Kim Conley, a member of Team New Balance and U.S. Olympic runner, thinks so.

After initially coming in to the Sports Research Lab at New Balance for the simulation testing in 2012, Conley first wore her customized spike plates for competition in 2013 at the Mt. SAC Relays and has continued to wear them, especially at such important races as the World Championships.

“My shoes are critical to my performance. They’re the most important piece of equipment I have,” says Conley. “As a professional runner, you obviously want the most effective and comfortable spike plates for competition. For me, these are the ones New Balance designed based on the curve running data their development team had collected. They provide better traction and less pressure on the outside of my foot, which allows me to focus on my race plan and not worry about my spike plates.”

Conley has run personal records (PRs) in both the 3000m (8:44.11) and 5000m (15:08.61) wearing her laser-sintered spike plates. She also wore them at the 2013 World Championships, where she had her best international performance to date.

A Perfect Fit

What does all this mean for the amateur or recreational runner? While runner-specific spike plates are currently only available for Team New Balance athletes, Petrecca says this will eventually change.

“Design-driven additive manufacturing really holds the promise of more on-demand production and more individually customized design,” she says. “These spike plates are the first step we’ve taken with our athletes to prove that out. As the material options expand; as our own proficiency with the technology expands; as capacities for additive manufacturing grow, we believe we will be able to bring 3D-printed products, in some format, to the everyday consumer.”

Runners won’t be the only ones having all the fun. Petrecca notes that there is definitely the opportunity to expand the customization practices developed on the spike-plate project to other sports. However, the repetitive motion of running along the track doesn’t always happen in other athletic events—where participants are required to quickly change direction, pivot, back-pedal, or shuffle side to side—which could present a number of data-collection challenges.

“There is still a significant amount of progress that needs to be made in order to get groundbreaking products like this to the consumer,” says Petrecca, “but seeing these customized plates on the feet of elite athletes is a tangible example of a next generation of products: additively manufactured, performance-customized products that could allow every runner to have a shoe that is uniquely their own.”