Consolidation through strategic acquisitions is nothing new in the CAD world, though I must admit to being surprised by last week’s announcement that ANSYS, a world leader in simulation technology, had acquired SpaceClaim Corp. for $85 million in cash. The transaction closed on April 30.

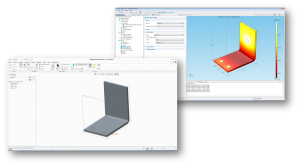

SpaceClaim took the “direct” approach to 3D modeling

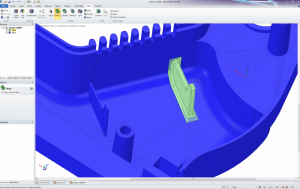

SpaceClaim introduced direct modeling to the masses with the introduction of SpaceClaim 2007 Professional back in 2007. SpaceClaim, which my colleague Josh Mings referred to as “the company slapping the history out 3D modeling,” was founded in 2005 by industry big-wig Mike Payne, who also helped start up PTC and SolidWorks. The goal was to offer a 3D modeling tool that could be used by more than just CAD experts.

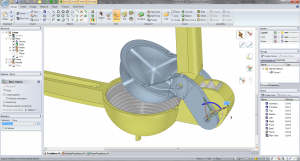

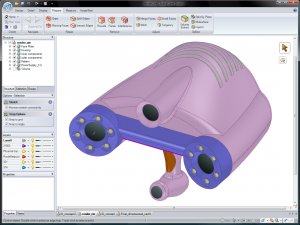

ANSYS and SpaceClaim have partnered up in the past to offer customers ANSYS SpaceClaim Direct Modeler as an option to ANSYS customers. These users, who are mostly analysts, work in 3D but didn’t want to become experts in traditional, feature-based CAD systems. With the software, users could create and modify 3D geometry models without needing to learn the complexities of the CAD software.

By enabling ANSYS users to create and modify 3D models, simulation can be done upfront in the product development process, where the biggest payoffs (performance, cost and time-to-market) can be realized. The vision of ANSYS has always been to enable companies to leverage the value of computer simulation early in the design process to predict how a product will perform in the real world.

By adding SpaceClaim to its product line, ANSYS customer will have a 3D direct modeling tool for creating new concepts and then performing simulation on those models to iterate and optimize product designs. In addition, because ANSYS has always been an essentially open platform and SpaceClaim’s solutions are also relatively CAD-neutral, users can modify geometries regardless of what system was used to create them.

Benefits of acquisition

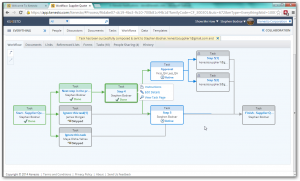

* Acceleration of ANSYS’ technological product roadmap and long-time vision for Simulation Driven Product Development. SpaceClaim can help simplify and automate what has traditionally been a time-consuming process of preparing geometry for use in a simulation system, enhancing ease-of-use to help ANSYS accelerate product adoption and the growth of the simulation market overall. The transaction enables ANSYS to accomplish what would have taken the company many years (if ever) to develop alone.

* Enhanced customer offering through complementary technologies. The transaction enablesANSYS to provide its customers with a 3D direct modeling solution to author new concepts and then leverage simulation to iterate on these designs.

* Drives growth through an expanded customer base and cross-selling opportunities. The broad appeal of SpaceClaim’s technology can help ANSYS deliver simulation tools to any engineer in any industry – at the earliest stages of the design cycle – expanding ANSYS’ user base from analysts and expert users to 5 million design and systems engineers.

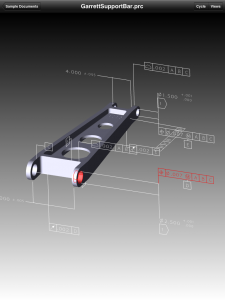

* Increased innovation. SpaceClaim’s flagship product is SpaceClaim Engineer, 3D direct modeler, and offers UI/UX design for both 3D applications and mobile devices.

Of those proposed benefits, I think the one that stands out as obvious is the fact that acquiring SpaceClaim expands ANSYS’ user base from analysts and expert users to five million design and system engineers. We’ll certainly be watching to see how this shakes and out and will keep you updated on any new product announcements made as a result of this union.

For more information, check out the official press release from ANSYS.