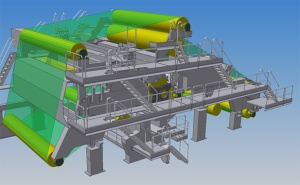

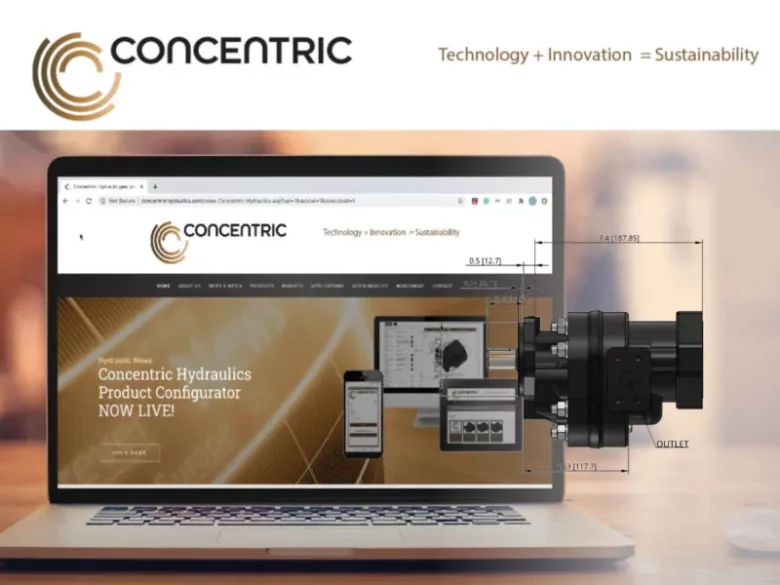

Concentric AB, an innovator in flow control and fluid power, supplying proprietary systems and components to the world’s truck, bus, agricultural machinery, construction equipment, and industrial applications end-markets, provides a CAD download tool built by CADENAS PARTsolutions. A customer-focused manufacturer best known for their external gear pumps and motors, Concentric has offered an industry-leading customer experience by delivering custom hydraulic solutions which accelerate speed to market for design engineers.

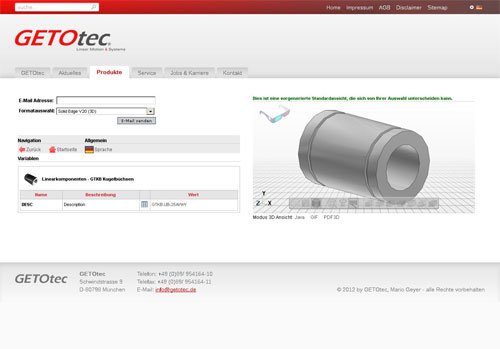

“Our mission is to provide custom and innovative solutions to meet our customer’s needs. We’re building upon that by providing this new 3D CAD configurator online. The hydraulic configurator tool has run successfully from our website,” said Sid Moate, director of key accounts and marketing at Concentric Rockford Inc. “Over the past three years, we have seen downloads in excess of 5,770 from over 60 countries worldwide.”

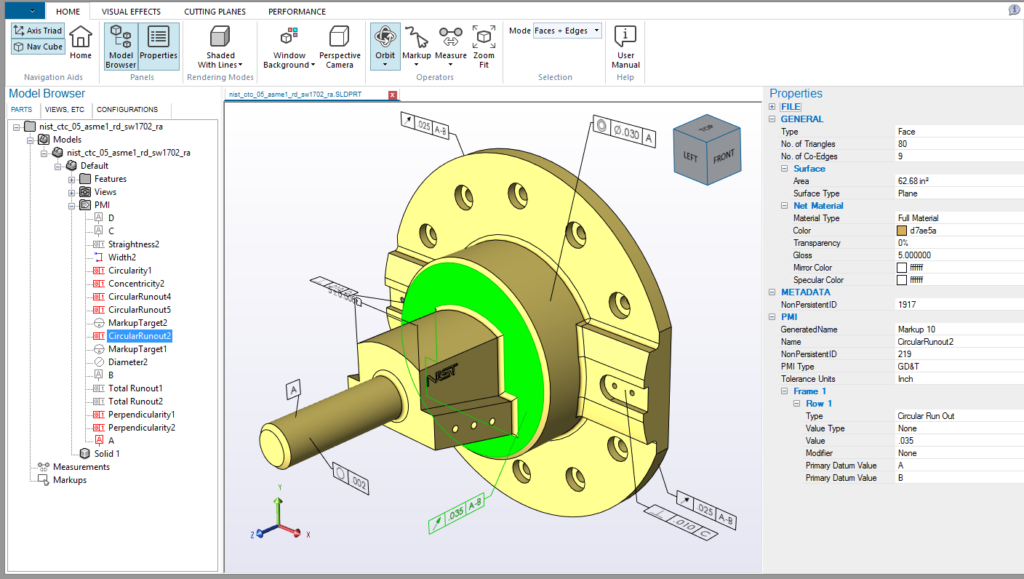

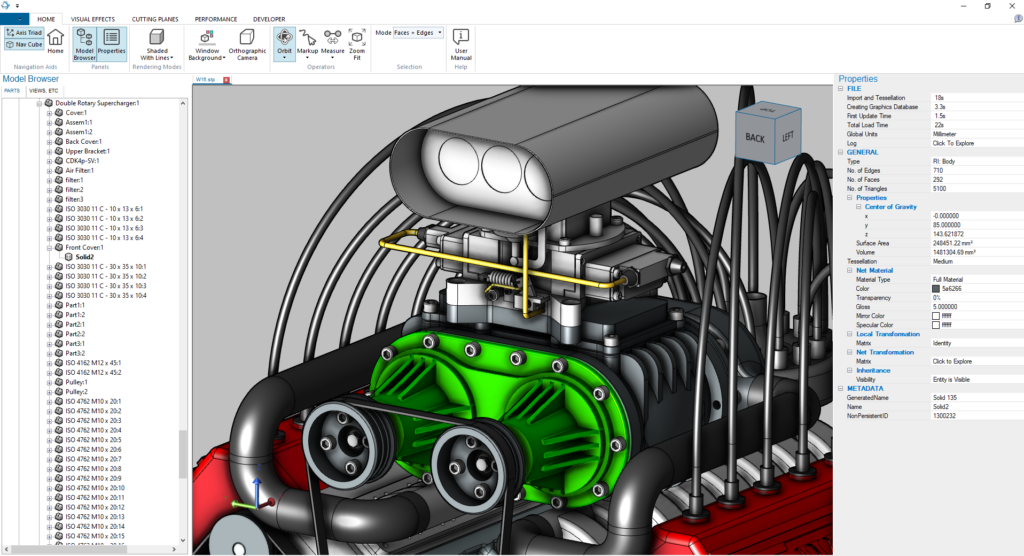

The tool enables engineers to find, configure, and generate an interactive 3D product preview on-demand before downloading a CAD file for use within their design. In addition to 3D CAD files, engineers can also download a configured 3D PDF datasheet for their purchasing department or anyone without a CAD system.

“We’re excited to provide new deliverables like 3D PDF datasheets too. It’s important to deliver exactly what the customer needs. The configured drawings have all of the dimensions and information needed for engineers and designers to make decisions,” said Moate.

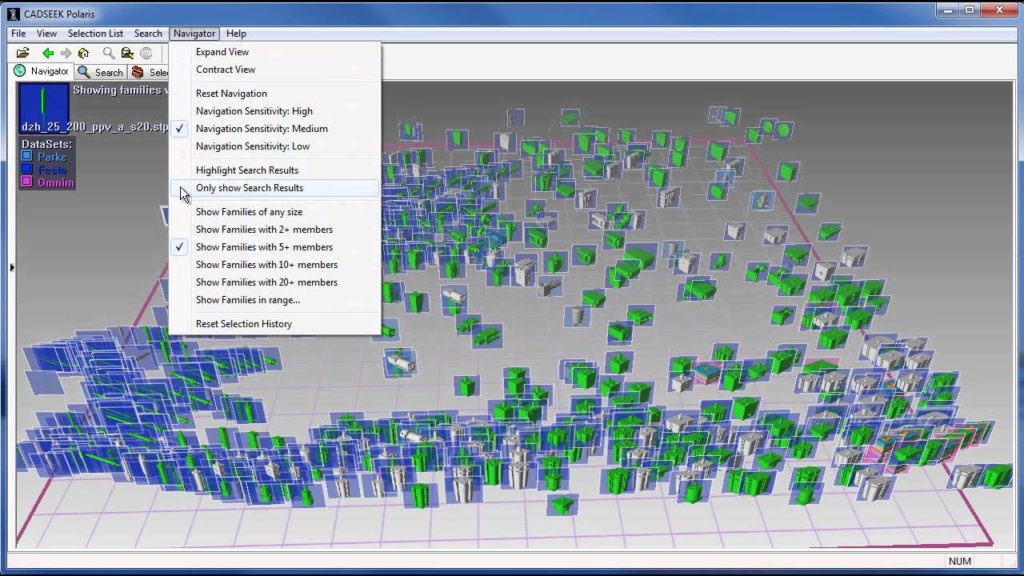

Concentric has more than 30 product families available in the CAD tool, with millions of configuration options available.

“Since we added the new hydraulic product configurator online, we’ve had engineers design and download CAD from new countries that we’ve never done business with before. This product configurator offers value to customers globally, expanding our worldwide reach,” said Moate.

Concentric AB

concentricab.com

CADENAS PARTsolutions

partsolutions.com