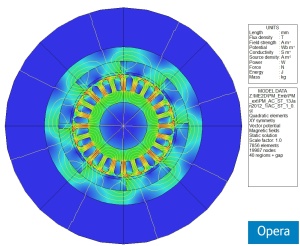

Cobham’s Machines Environment introduced a new level of user friendliness when it was launched by providing a design entry system that allows precision FEA models of motors and generators to be created and solved in minutes. The 2D version of the software has now been integrated with Cobham’s optimization tool which automatically finds the optimal solution within a design space – even for multiple or competing design objectives.

The software is an application-specific extension to the Opera electromagnetic simulation package. It provides a front-end to the simulator that speeds design entry by means of Wizard-style dialog boxes. Users select the style of motor or generator they want to design from a library of all common types, including induction, brushless permanent magnet and switched reluctance motors, and synchronous motors or generators. Then, dialog boxes allow you to enter parameters to define mechanical geometry, material properties and electrical data, and the FEA model is automatically created.

The use of parameterized models and the ability to load and modify previous designs have made it possible for users to perform ‘what-if?’ design investigations. Cobham has integrated a unique optimization tool that makes it simple for users to find the best solution across the design space. While auto-optimization tools are not new, they usually require manual intervention if the globally optimal solution is to be found, and the simulation times involved often make this impractical. The Optimizer selects and manages multiple goal-seeking algorithms including stochastic, descent, particle swarm, and Kriging to eliminate the need for manual intervention.

Setting up an Optimizer run from the Machines Environment is easier. Because most FEA simulations can take as little as a few seconds, the integrated software makes it possible to thoroughly explore the design space. Thousands of simulations can typically be executed within hours, making the perfect solution achievable for all users – without expert assistance.

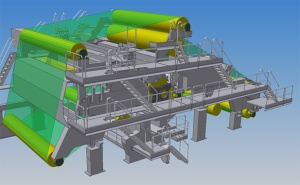

The 2D Machines Environment has an extensive library of rotating machine design styles and design components. However, if there are still any unusual features that need to be incorporated in designs, users also have open access to the scripts that generate the models, and can modify them at will to automate proprietary motor and generator design concepts. A library of common material properties is also included in the design software. Again, if users employ any special materials, such as an unusual grade of steel for laminations, then a new menu item can be created. Cobham will also generate custom scripts for users on request. A 3D version of the Machines Environment is available.

Cobham Technical Services

www.cobham.com/technicalservices