With all the excitement at full tilt with the 2014 FIFA World Cup underway in Brazil, the whole world seems to have gone soccer-crazy, with many people hitting local fields to practice their own ball-handling skills. At Graz University of Technology in Austria, that includes robots. The university is designing and building robots to be superior “soccer players.”

No water bottles required

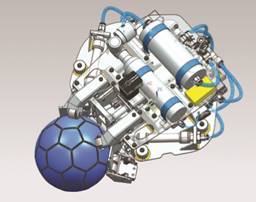

Propelled by omnidirectional roller drives, the robots are fully autonomous and carry everything on board, from the power supply to the compressed air bottle for the kicking mechanism. The only input from the outside are the referee’s commands.

The need for well-defined, easy-to-communicate rules is critical for testing the efficacy of autonomous robots from an artificial intelligence perspective. Most of all, the test environment must provide changeable conditions that closely mirror reality. The game of soccer fulfills these conditions.

Battling for victory in the RoboCup

The RoboCup competition was established in the 1990s as a test bed for research, development and university education. Matches strictly follow FIFA rules and are played in various categories. Playing soccer, however, is not the point. The goal is to design methods for autonomous robots that can quickly make correct decisions based on their observations.

For now, robots play against robots in these tournaments. However, a challenge has already been announced: In 2050, a team of robots is scheduled to play the human team holding the World Cup at the time. One team from the university has been participating in the world championship since 2003.

Tackling a new robot design required the team to improve their mechanical design process. “The older robot generations were created with a mix of 3D CAD modeling and hand drawings,” says Norbert Rath, head of mechanical engineering within the group. “This involved using a CAD system that is particularly unwieldy and forces users to employ strictly parametric methods.”

Searching for a better design tool

The CAD tool the team used in the past also had certain shortcomings in drawing conversion. Due to high application complexity, work could not commence without an enormous amount of training and familiarization.

With frequent staff changes, the team searched for an alternative that would provide high-functional capabilities, while being easy to learn with minimal training requirements, along with the ability to distribute work so that multiple team members could contribute to the overall task without requiring significant coordination efforts.

As a result, in early in 2009, the RoboCup team licensed NX software from Siemens PLM Software. Adopting the use of NX, Graz University of Technology students reported significant benefits, which included: reduced data preparation work from a week to a day; improved data efficacy; facilitated collaboration between team members; reduced number of physical prototypes; and optimized budget and resources.

To learn more about Siemens NX software, click here.